A Comprehensive Guide to Control Arms

What is a control arm?

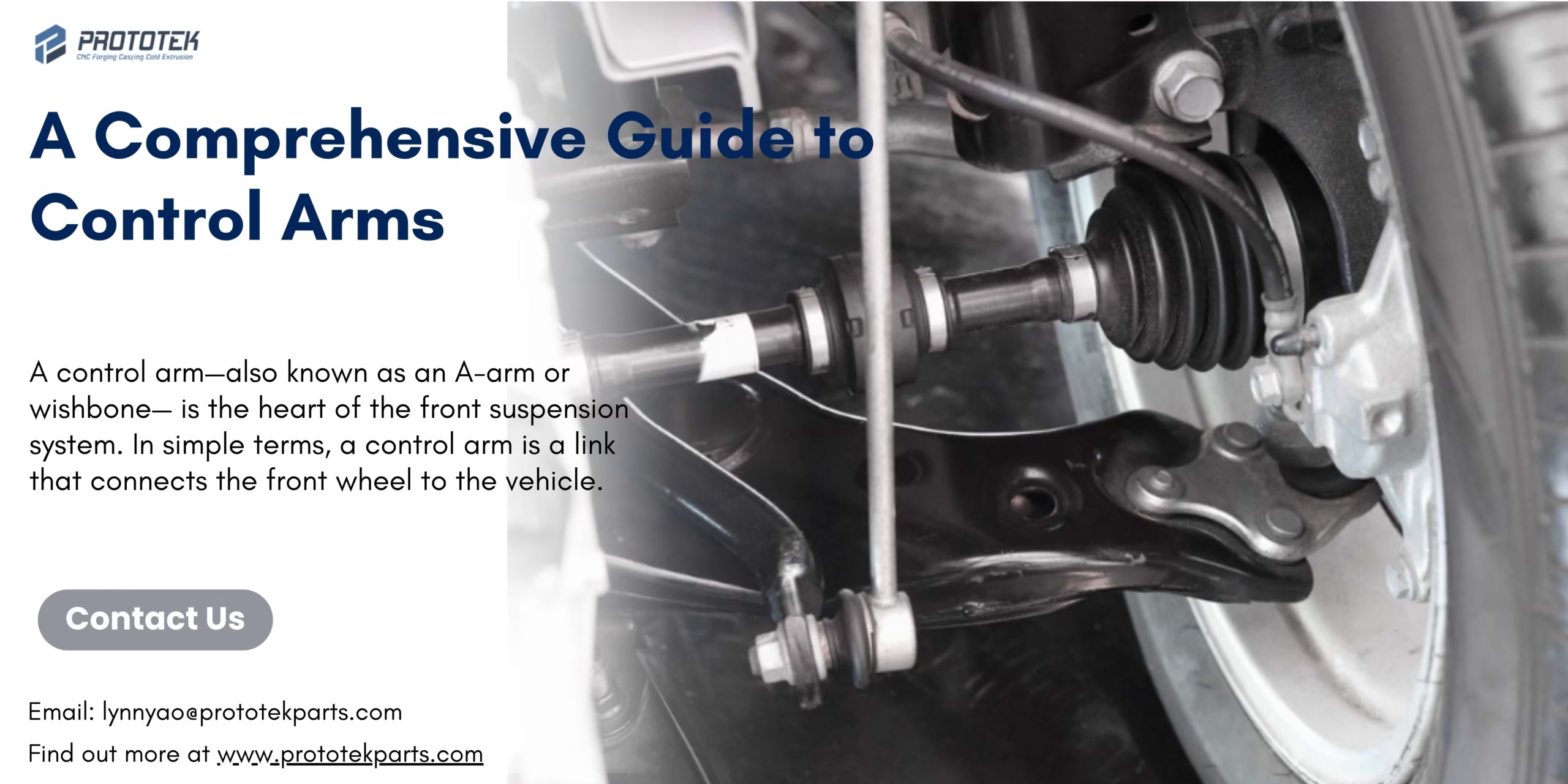

A control arm—also known as an A-arm or wishbone— is the heart of the front suspension system. In simple terms, a control arm is a link that connects the front wheel to the vehicle. It is connected to the wheel assembly on one end and to the vehicle’s frame on the other.

The upper control arm is connected to the top of the front wheel, the lower control arm is connected to the bottom of the front wheel, and both control arms are connected to the frame. If you have an independent rear suspension, the design is similar.

Control arms help absorb shocks from the road and play a major role in vehicle steering, handling, and comfort.

What are the types of control arm suspensions?

The most common types of control arm suspensions are:

- Control arm suspension

- Strut suspension

Control arm suspension is divided into the upper control arm & lower control arm

Vehicles may have one or both, depending on the suspension type. Most front suspensions use lower control arms; double-wishbone systems use both.

Also divided into OEM vs Aftermarket

OEM (Original Equipment Manufacturer) arms offer perfect fitment and durability.

Aftermarket control arms provide more flexible pricing and customization options.

Strut designs have a lower control arm but no upper control arm. In a strut design, the strut acts as the upper control arm and is sometimes connected directly to the spindle or lower control arm.

How do control arms work?

- Each control arm is connected to the vehicle frame via two control arm bushings. These bushings allow the control arm to move up and down.

- The other end of the control arm is connected to a steel spindle. The front wheel is bolted to the spindle. On vehicles not equipped with shock absorbers, the spindle is connected to the upper and lower control arms via ball joints. The ball joint is a steel ball enclosed in a steel sleeve that allows the spindle and front wheel to rotate from side to side and allows the wheel to move up and down along the road surface.

- Sandwiched between the control arm and the frame is a heavy steel coil spring that sits in a spring seat to support the weight of the vehicle and provide cushioning.

To ensure perfect alignment of the control arms, bushings, and ball joints, some control arms have adjustable attachment points on the frame. If necessary, a technician can adjust the front end to ensure your vehicle stays straight on the road.

Symptoms of a Bad Control Arm

Timely replacement is crucial. Here are common signs of control arm failure:

- Clunking or knocking noises while driving over bumps

- Steering wheel vibration at higher speeds

- The vehicle is pulling to one side

- Uneven tire wear

- Loose or wandering steering

If these symptoms appear, the control arm or its bushings/ball joints may be worn or damaged.

When and Why to Replace Control Arms

Control arms generally last 80,000–150,000 kilometers, depending on driving conditions and load. It’s important to:

- Replace them if any signs of cracking, bending, or bushing failure appear

- Check them during major suspension overhauls

- Use high-quality replacements that meet or exceed OEM specs to ensure safety

How to diagnose control arm problems?

A technician may diagnose control arm wear during a test drive of the vehicle. It may also be seen during a hop test, where the technician pushes hard on one corner of the vehicle to bounce the suspension and rotate the control arm. Because control arms determine the position and angle of the wheels, a damaged or bent control arm may be discovered during a four-wheel suspension alignment.

How is a control arm replaced?

The technician will first lift the vehicle in the air and then remove the wheel and tire before replacing the lower control arm. The lower control arm must be disconnected from the lower ball joint (which is attached to the steering knuckle) and the frame or body of the vehicle. The upper control arm is disconnected from the strut tower on the body and the top of the steering knuckle. Some control arms have built-in bushings, while others require bushings to be installed. When replacing a control arm, related parts such as the ball joint, tie rod joint, and stabilizer link are usually replaced at the same time.

Control Arm Manufacturing: What Makes a Good Product?

When sourcing control arms for export or wholesale, look for:

Material Quality

Forged aluminum or high-grade steel with proper corrosion resistance (e.g., electrophoretic coating)

Precision Manufacturing

- CNC machining for exact tolerances

- Robotic welding or casting for consistent quality

Ball Joint and Bushing Integration

- Durable rubber or polyurethane bushings

- Pre-assembled joints for easy installation

Certifications & Testing

- ISO/TS 16949 certified production

- Fatigue and impact testing

- Salt spray resistance test (≥ 500 hours)

How to Choose the Right Control Arm Supplier?

Whether you’re importing for your retail brand or supplying to repair networks, consider:

- Product Range

Does the supplier cover all major car models (e.g., Ford, Toyota, BMW, Hyundai)?

- MOQ & Lead Time

Flexible minimum order quantity and fast delivery cycles

- Customization & Packaging

Private label, barcode stickers, brand packaging

- Warranty & After-Sales Support

At least a 12-month warranty is preferred for international buyers

- Factory Capabilities

Visit or audit the factory to assess QC, automation level, and output capacity

If you have any needs, contact us via email at Lynnyao@prototekparts.com or phone: +86-0792-86372550

Tags:

- control arms