Détails du blog

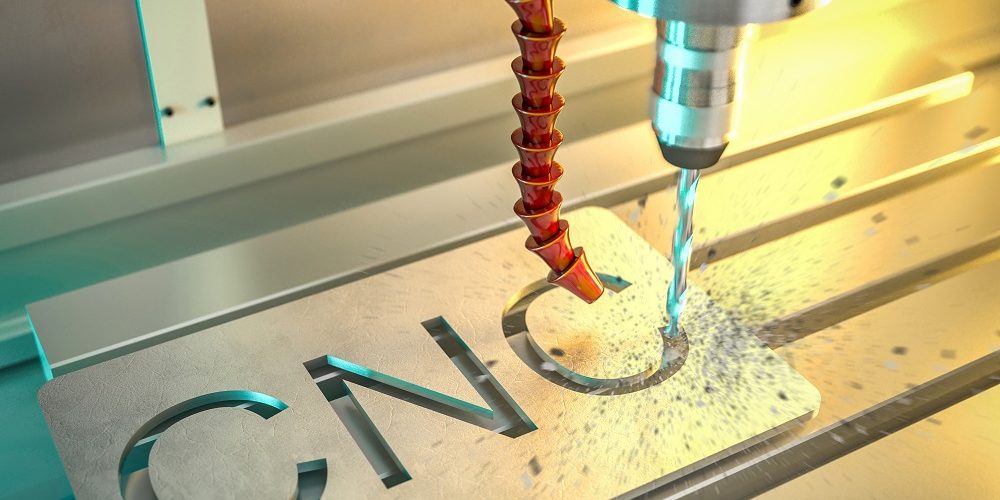

The Essential Guide to CNC-Turned Parts Manufacturers

In the manufacturing realm, CNC-turned parts play a pivotal role, and understanding the nuances of the manufacturers behind them is crucial. This article is a comprehensive guide to navigating the world of CNC-turned-part manufacturers, shedding light on their processes, technologies, quality control measures, industry trends, and prospects.

The Craftsmanship Behind CNC Turning

CNC turning, as a fundamental process in modern manufacturing, embodies a meticulous blend of craftsmanship and technological precision. At its core, CNC turning involves the removal of material from a workpiece to achieve the desired shape and dimensions. What distinguishes CNC from conventional methods is the utilization of computer numerical control (CNC) technology, which enables unparalleled accuracy and repeatability in part production.

Precision Engineering

Central to the craftsmanship of CNC turning is precision engineering. Manufacturers meticulously program CNC lathes, the primary machines used in turning operations, to execute precise tool movements. These movements are orchestrated to remove material from the workpiece in a controlled manner, resulting in components with tight tolerances and impeccable surface finishes. The ability to achieve micron-level precision is a hallmark of CNC turning, making it indispensable in industries where accuracy is paramount, such as aerospace, automotive, and medical device manufacturing.

Material Mastery

Another facet of CNC-turning craftsmanship lies in material mastery. CNC-turned parts are crafted from a wide array of materials, including metals like aluminum, steel, and titanium, as well as plastics such as nylon and polycarbonate. Each material presents challenges and considerations, from tool selection to cutting speeds and feeds. Experienced CNC machinists possess an intimate understanding of material properties and behavior, enabling them to optimize cutting parameters for maximum efficiency and quality.

Tooling Expertise

Tooling expertise is another crucial aspect of CNC-turning craftsmanship. Selecting cutting tools, inserts, and holders is pivotal in achieving optimal machining performance. Factors such as tool geometry, coating technology, and substrate material influence tool life, chip control, and surface finish. Moreover, the ability to strategically apply various cutting strategies, such as roughing, finishing, and profiling, requires a deep understanding of tooling principles and machining dynamics.

Process Optimization

Craftsmanship in CNC turning extends beyond individual machining operations to encompass process optimization. Manufacturers continuously refine their processes to minimize cycle times, reduce waste, and maximize productivity. This involves optimizing cutting parameters, such as spindle speed, feed rate, and depth of cut, to strike a balance between material removal rates and tool life. Additionally, leveraging advanced CAM (Computer-Aided Manufacturing) software allows for generating optimized tool paths, further enhancing efficiency and precision.

Continuous Improvement

Ultimately, the craftsmanship behind CNC turning is characterized by a commitment to continuous improvement. Manufacturers invest in training and skill development to keep pace with technological advancements and industry best practices. By embracing innovation and refining their craft, CNC machinists push the boundaries of what’s possible. Delivering precision-engineered components that drive progress across many industries.

Exploring CNC Turning Technology and Equipment

CNC turning technology and equipment constitute the backbone of modern manufacturing, offering unparalleled precision, versatility, and efficiency. This section delves into the intricacies of CNC-turning technology, highlighting the evolution of equipment and the innovative features that drive productivity and quality in the industry.

Evolution of CNC Turning Technology

The evolution of CNC turning technology has been marked by significant advancements in machine design, control systems, and cutting tool technology. Early CNC lathes were characterized by basic functionality and limited capabilities, but over the years, rapid technological progress has transformed the landscape of turning operations.

Multi-Axis Machining

One of the most notable advancements in CNC turning technology is adopting multi-axis machining capabilities. Traditional lathes can perform operations along two axes (X and Z). Still, modern CNC lathes can feature live tooling and additional axes (such as Y, B, and C), enabling complex machining operations in a single setup. Multi-axis machining offers greater flexibility, allowing manufacturers to produce intricate geometries and reduce the need for secondary operations.

Swiss-style CNC Lathes

Swiss-style CNC lathes have revolutionized the production of small, high-precision components. These machines excel at machining long, slender parts with tight tolerances, such as medical implants, aerospace components, and electronic connectors. Swiss-style lathes feature a sliding headstock and guide bushing, which provide enhanced support and stability during machining. Additionally, integrating advanced control systems and servo motors ensures precise synchronization of tool movements, resulting in superior surface finish and dimensional accuracy.

Automatic Bar Feeders

Automatic bar feeders are integral to CNC turning equipment, streamlining production and maximizing machine uptime. These devices automatically load raw material, typically round bars or tubes, into the lathe, allowing for continuous and unattended operation. Automatic bar feeders come in various configurations, including pneumatic, hydrodynamic, and servo-driven systems, each offering unique advantages in speed, reliability, and material handling capabilities.

Live Tooling and Sub-Spindles

Live tooling and sub-spindles enhance the versatility of CNC turning machines, enabling the performance of milling, drilling, and tapping operations in addition to traditional turning. Live tooling units are equipped with rotating tool holders that can engage the workpiece at various angles, expanding the range of machining capabilities. Sub-spindles, on the other hand, provide the ability to perform secondary operations on the reverse side of the workpiece, eliminating the need for manual intervention and reducing cycle times.

Integration of Automation and Robotics

The integration of automation and robotics has further transformed CNC turning operations, enabling lights-out manufacturing and enhancing productivity. Automated loading and unloading systems, robotic arms, and vision systems facilitate seamless material handling and part inspection. Additionally, collaborative robots (cobots) are increasingly deployed alongside human operators to perform repetitive tasks and enhance overall efficiency on the shop floor.

Ensuring Quality in CNC-Turned Parts at Prototek

Quality assurance is a cornerstone at Prototek in CNC-turned-part manufacturing, as precision and reliability are paramount in meeting customer expectations and industry standards. This section delves into the various measures and techniques Prototek employs to uphold stringent quality standards throughout production.

Dimensional Inspection

Dimensional inspection is the bedrock of quality assurance at Prototek in CNC-turned parts manufacturing. Manufacturers utilize various precision measurement tools, such as coordinate measuring machines (CMMs), calipers, micrometers, and optical comparators, to verify the dimensional accuracy of machined components. Automated inspection systems with advanced metrology software enable rapid and precise measurement of critical features, ensuring compliance with tight tolerances and specifications.

Surface Finish Analysis

Surface finish analysis is essential for assessing the quality and aesthetics of CNC-turned parts at Prototek. Manufacturers employ surface profilometers and roughness testers to quantify surface texture and roughness parameters, such as Ra (average roughness) and Rz (maximum roughness depth). Manufacturers achieve the desired surface finish requirements by meticulously controlling machining parameters, such as cutting speed, feed rate, and tool geometry, ranging from smooth mirror finishes to textured surfaces tailored to specific applications.

Material Testing and Certification

Material testing and certification are pivotal in ensuring the integrity and performance of CNC-turned parts at Prototek. Manufacturers conduct material analysis and mechanical testing to verify material properties, such as hardness, tensile strength, and chemical composition. Certified raw material suppliers provide material certifications (mill certificates) that document material traceability and compliance with industry standards, such as ASTM, ISO, and AMS specifications. By sourcing materials from reputable suppliers and performing rigorous material testing, Prototek mitigates the risk of material-related defects and ensures the quality of finished components.

Statistical Process Control (SPC)

Statistical Process Control (SPC) methodologies enable manufacturers at Prototek to monitor and control manufacturing processes in real-time, ensuring consistent quality and identifying potential deviations before they impact product quality. SPC techniques, such as control charts, process capability analysis, and Pareto analysis, allow manufacturers to analyze process variability, identify root causes of defects, and implement corrective actions proactively. Manufacturers optimize process parameters, minimize variation, and enhance product quality and reliability by harnessing data analytics and statistical techniques.

Quality Management Systems (QMS)

Quality Management Systems (QMS) provide a framework for implementing and maintaining quality assurance processes and procedures throughout the organization at Prototek. Manufacturers adhere to international quality standards, such as ISO 9001, AS9100, and IATF 16949, which outline requirements for quality management systems in various industries. QMS encompasses a range of activities, including document control, non-conformance management, corrective and preventive actions (CAPA), and internal audits, to ensure consistency, traceability, and continuous improvement in product quality and customer satisfaction.

Certifications and Compliance

Certifications and compliance demonstrate Prototek’s commitment to quality and regulatory requirements. CNC-turned-parts manufacturers undergo third-party audits and certifications to validate their adherence to industry standards and customer specifications. Certifications, such as Nadcap (National Aerospace and Defense Contractors Accreditation Program), demonstrate compliance with stringent aerospace industry requirements. Additionally, compliance with regulatory standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), ensures CNC-turned parts’ safety and environmental sustainability.

Navigating the CNC-Turned Parts Market

The CNC-turned-parts market witnesses dynamic shifts driven by technological advancements and changing consumer demands. Industry players must stay attuned to emerging trends, such as the rising demand for lightweight and eco-friendly materials. Additionally, globalization opens avenues for collaboration and competition, reshaping the market dynamics.

Selecting the Right CNC-Turned Parts Manufacturer

Choosing a suitable CNC-turned-parts manufacturer necessitates a discerning approach. Factors such as machining capabilities, quality assurance protocols, lead times, and cost-effectiveness warrant careful consideration. Collaborating with a reliable manufacturer ensures seamless project execution and fosters long-term partnerships.

Future Outlook and Challenges

As technology advances, the future of CNC-turned-parts manufacturing appears promising yet riddled with challenges. Industry players must adapt to disruptive innovations, such as additive manufacturing and artificial intelligence, to stay relevant. Furthermore, addressing sustainability concerns and geopolitical uncertainties poses formidable challenges.

CNC-turned-parts manufacturers play a pivotal role in shaping the modern manufacturing landscape. By embracing technological innovations, upholding stringent quality standards, and staying attuned to market trends, they navigate the industry’s complexities with resilience. As we look ahead, the future of CNC-turned-parts manufacturing holds immense potential, underpinned by innovation, collaboration, and adaptability.

Si vous avez des besoins, contactez-nous par e-mail : Lynnyao@prototekparts.com ou par téléphone : +86-0792-86372550

Tags :

- Stainless Steel Parts