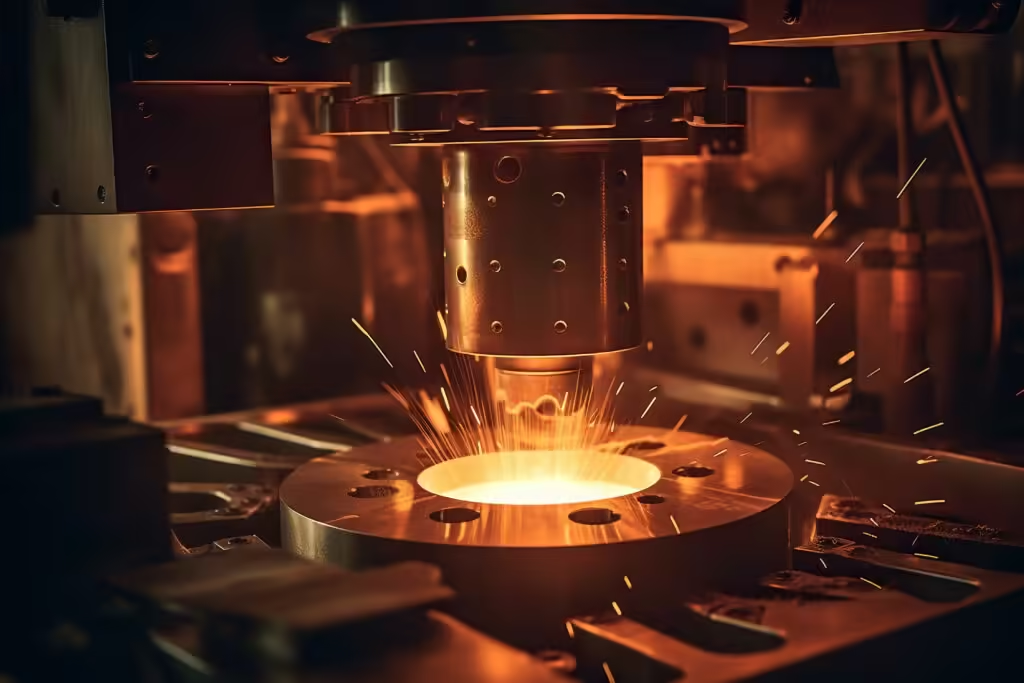

What is Hot Forging

Hot forging is a metalworking technique used to shape metal parts at high temperatures. This technique has become essential across multiple manufacturing industries due to its ability to enhance material properties while creating complex shapes with precision. Here we will examine more deeply its principles, features, materials, surface treatment, and market applications.

How hot forging works?

Temperature Range

Hot forging involves heating metal above its recrystallization temperature – typically 800-1200degC for steel – to make sure that it remains flexible and resistant to deformation. This high temperature ensures a pliable yet deformation-resistant metal is formed.

Pressure Application

Compressive forces may be applied through equipment like hammers, hydraulic presses, or mechanical presses in this process of forging products. Both force and speed of application play an essential part in determining product quality.

Deformation Process

Metals exposed to temperatures above about 800F undergo plastic deformation and dynamic recrystallization processes that improve grain structures while increasing the mechanical properties of the metal.

Equipment and Tools

Common equipment includes drop hammers, hydraulic presses, and mechanical presses. Molds or dies made of high-strength tool steels are essential in shaping metal to the desired form.

Features

1. High Strength and Toughness

Hot-forged materials exhibit superior strength and toughness compared to those produced by other forming processes. This is due to the refined grain structure and the elimination of porosity.

2. Excellent Formability

The process allows for the creation of complex shapes and large components that would be challenging to achieve through cold forming.

3. Material Efficiency

Hot forging maximizes material utilization by minimizing waste, making it an economically favorable manufacturing method.

4. Defect Reduction

The high temperatures and pressures can eliminate or reduce internal defects, resulting in higher-quality end products.

materials

Commonly Used Materials

Steel and Alloys:

Carbon steel, alloy steel, stainless steel.

Carbon Steel

AISI 1045: A medium carbon steel with good strength and hardness.

AISI 1060: A high carbon steel, commonly used in the manufacture of cutting tools and springs.

Alloy Steels

AISI 4140: A chromium-molybdenum steel with high strength and good toughness, widely used for automotive and mechanical parts.

AISI 4340: nickel-chromium-molybdenum alloy steel, suitable for parts requiring high strength and toughness.

Stainless Steels

AISI 304: the most common stainless steel with good corrosion resistance and weldability.

AISI 316: Molybdenum-containing stainless steel with higher corrosion resistance, suitable for marine and chemical environments.

Aluminum Alloys:

Used for lightweight and corrosion-resistant parts.

Aluminum Alloy 6061: Commonly used malleable aluminum alloy with good mechanical properties and corrosion resistance.

Aluminum Alloy 7075: High strength aerospace aluminum alloy, widely used in aerospace applications.

Copper Alloys: Excellent for electrical and thermal conductivity applications.

Brass

C260: A commonly used brass alloy with good formability and corrosion resistance.

C360: Cutting brass, suitable for parts requiring high precision machining.

Bronze

C932: a commonly used bronze alloy with good wear resistance and strength.

C954: Aluminum bronze with very high strength and corrosion resistance

Nickel Alloys:

Known for high-temperature and corrosion resistance.

Inconel 718

High-temperature alloy with excellent heat and oxidation resistance, widely used in aero-engine components.

Monel 400

Corrosion resistant nickel alloy, commonly used in marine and chemical equipment.

Titanium Alloys

Valued for their strength-to-weight ratio and corrosion resistance.

Ti-6Al-4V: The most commonly used titanium alloy with high strength and light weight, widely used in aerospace and biomedical equipment.

Ti-5Al-2.5Sn: Valued for their high-temperature properties and suitable for applications in high-temperature environments.

Material Selection Criteria

The choice of material depends on the specific application requirements, including temperature resistance, mechanical properties, and cost-effectiveness.

Surface Treatment in Hot Forging

Surface treatment is a crucial step in the hot forging process, aimed at enhancing the performance, appearance, and longevity of forged parts. It involves several techniques to clean, harden, and protect the surface of the metal. Here, we’ll delve deeper into the various methods of surface treatment, with a particular focus on surface coating.

Oxide Scale Removal

During hot forging, the high temperatures cause the formation of oxide scales on the metal surface. These scales need to be removed to ensure a clean and smooth surface.

Mechanical Cleaning: Techniques such as shot blasting or grinding are used to mechanically remove the oxide scales. This method is effective for large-scale production where surface roughness is not a critical issue.

Chemical Cleaning (Pickling): Acid solutions, such as hydrochloric or sulfuric acid, are used to dissolve the oxide scales. Pickling provides a clean and smooth surface, suitable for further surface treatments.

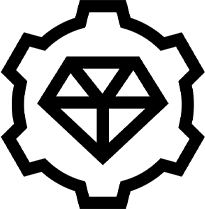

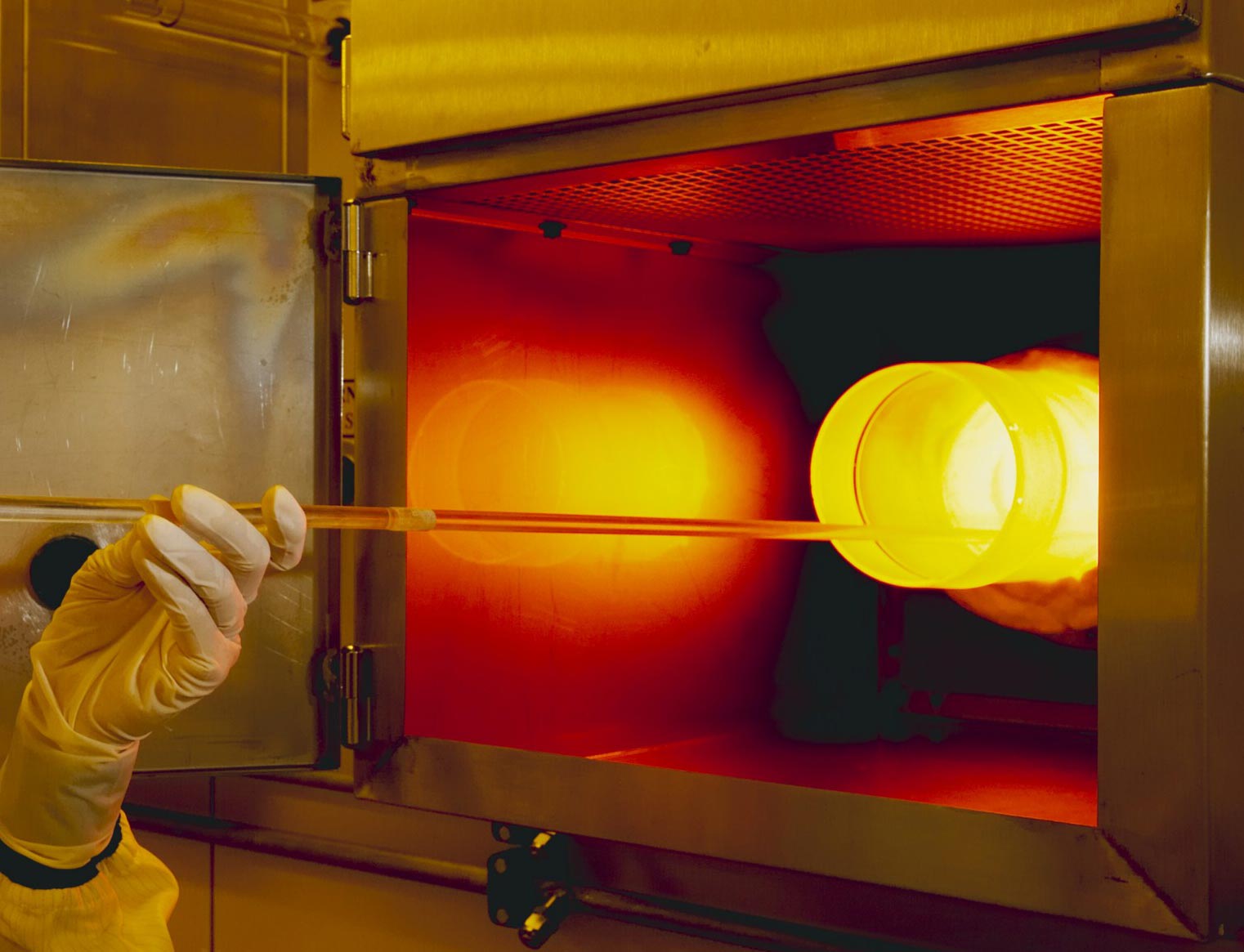

Heat Treatment

Heat treatment processes are applied to improve the mechanical properties of the forged parts and to relieve internal stresses.

Annealing: This process involves heating the forged part to a specific temperature and then slowly cooling it. Annealing improves ductility and reduces hardness, making the material easier to machine.

Normalizing: The forged part is heated to a temperature above its recrystallization point and then air-cooled. Normalizing refines the grain structure and enhances mechanical properties.

Quenching and Tempering: Quenching involves rapid cooling of the forged part in water or oil to increase hardness. Tempering follows quenching and involves reheating the part to a lower temperature to improve toughness and reduce brittleness.

Annealing

Normalizing

Quenching and Tempering

Surface Coating

Surface coating is applied to enhance the surface properties of forged parts, such as corrosion resistance, wear resistance, and aesthetic appeal.

There are several types of surface coatings used in hot forging:

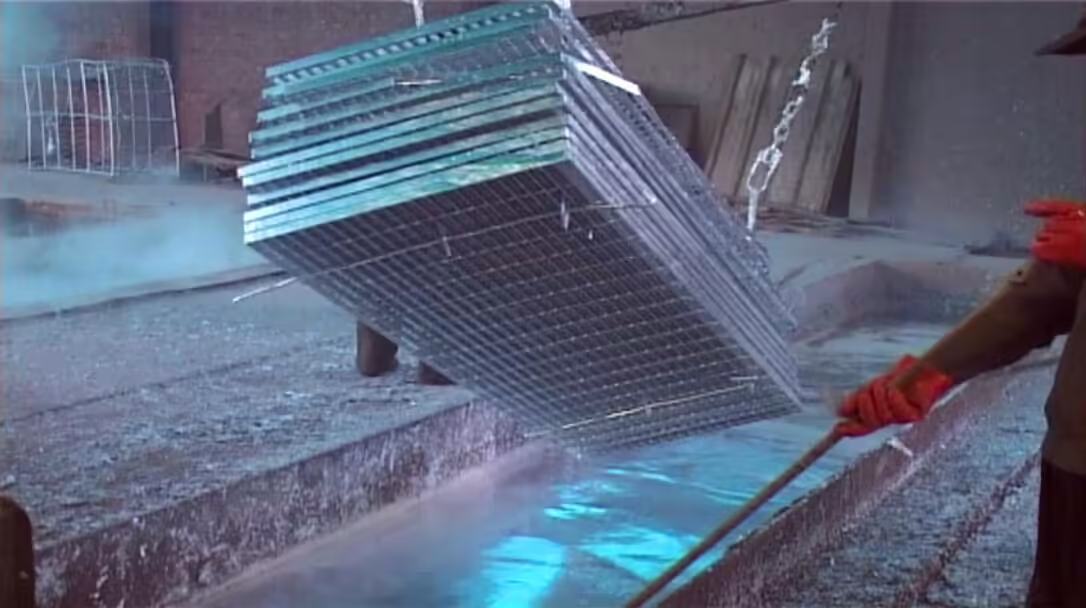

Galvanizing

Hot-Dip Galvanizing: The forged part is dipped in molten zinc, which forms a protective zinc coating. This method provides excellent corrosion resistance, making it ideal for outdoor and marine applications.

Electrogalvanizing: A thinner zinc layer is applied using an electrochemical process. This method is suitable for applications where a smoother finish and aesthetic appearance are important.

Plating

Nickel Plating: A layer of nickel is electroplated onto the forged part. Nickel plating enhances corrosion resistance, hardness, and provides a bright, attractive finish.

Chrome Plating: Chromium is electroplated onto the part, providing excellent hardness, wear resistance, and a shiny appearance. Chrome plating is commonly used in automotive and decorative applications.

Anodizing

Anodizing of Aluminum Alloys: This electrochemical process increases the natural oxide layer on the surface of aluminum parts, improving corrosion resistance and allowing for the addition of various colors.

Powder Coating

Process: The forged part is coated with a dry powder (typically a thermoplastic or thermoset polymer), which is then cured under heat to form a solid, durable layer.

Advantages: Powder coating provides excellent corrosion resistance, a wide range of color options, and a uniform finish. It is environmentally friendly compared to liquid paint, as it emits fewer volatile organic compounds (VOCs).

Spray Coating

Thermal Spray Coating: Molten or semi-molten materials (such as metals, ceramics, or polymers) are sprayed onto the surface of the forged part. This method is used to enhance wear resistance, corrosion resistance, and thermal barriers.

PVD (Physical Vapor Deposition): A thin, hard coating is deposited onto the surface of the forged part in a vacuum chamber. PVD coatings, such as titanium nitride or chromium nitride, offer excellent hardness and wear resistance, often used in cutting tools and high-performance applications.

Chemical Vapor Deposition (CVD)

Process: A thin film is formed on the surface of the part by chemical reactions of vapor-phase precursors. CVD coatings are used for applications requiring high-temperature resistance and wear resistance.

Market Applications of Hot Forging

Hot forging is a versatile manufacturing process used across various industries due to its ability to produce high-strength, durable, and complex components. Here, we will explore the detailed applications of hot forging in several key markets.

The automotive industry is one of the largest consumers of CNC Turning services. The precision and efficiency of CNC Turning make it ideal for producing various automotive components.

- Engine Components

Crankshafts: Hot forging provides the necessary strength and durability for crankshafts, essential for converting linear piston motion into rotational motion.

Connecting Rods: These parts connect the piston to the crankshaft and must withstand high stress and impact.

Camshafts: Forged camshafts control the opening and closing of engine valves, requiring precision and strength.

- Transmission Parts

Gears: Hot forging produces gears with high strength and precision.

Shafts: Transmission shafts must be robust and fatigue-resistan.

- Suspension and Steering Components

Control Arms: Forged control arms provide durability and reliability in steering and suspension systems.

Steering Knuckles: These components must be strong to handle the stress of steering and suspension systems.

The aerospace industry demands high-performance materials that can withstand extreme conditions. Hot forging is ideal for producing such components.

Aircraft Structural Components

Landing Gear: Forged landing gear parts must withstand significant impact forces during landing.Wing Spars and Ribs: These structural components provide the necessary strength and support for aircraft wings.

Engine Components

Turbine Blades: Forged turbine blades in jet engines must endure high temperatures and stresses, requiring exceptional material properties.

Discs and Rings: Forged discs and rings in engines offer high strength and resistance to thermal fatigue.

Heavy Industry

Heavy industries, such as mining, construction, and energy, rely on hot forging for robust and durable components.

- Mining Equipment

Drill Bits and Hammers: Forged drill bits and hammers offer the necessary hardness and toughness for penetrating hard rock.Crusher Parts: Components like crusher jaws and cones are forged to withstand high impact and wear.

- Construction Machinery

Excavator Buckets: Forged buckets provide durability and resistance to wear and tear in harsh environments.Track Links and Chains: These parts must endure heavy loads and rough conditions, making forging an ideal manufacturing method.

Energy Sector

Turbine Shafts: Forged shafts in turbines are critical for power generation, requiring high strength and precision.

Pipeline Components: Forged flanges, fittings, and valves in pipelines ensure leak-free connections and durability under high pressure.

Construction Industry

Hot forging is crucial in the construction and infrastructure sector for producing strong and reliable components.

- Structural Steel Components

Beams and Columns: Forged structural elements provide the necessary strength and stability for buildings and bridges.

Reinforcement Bars: Forged rebar enhances the tensile strength of concrete structures.

- Bridge Components

Bridge Bearings and Joints: These forged components allow for movement and load transfer in bridges, ensuring longevity and safety.

- Pipe Fittings and Connectors

Flanges and Couplings: Forged pipe fittings provide leak-proof connections in plumbing and industrial pipelines.

Tools and Hardware

The tools and hardware industry benefits from hot forging by producing durable and high-performance tools.

- Hand Tools

Hammers and Wrenches: Forged hand tools are known for their strength, durability, and resistance to wear.

Pliers and Cutters: These tools require precision and toughness, which are achieved through forging.

- Industrial Tools

Machinery Components: Forged components in industrial machines, such as gears and shafts, ensure reliability and longevity.

Cutting Tools: Forged cutting tools, like chisels and punches, offer superior hardness and edge retention.

Marine Industry

The marine industry uses hot-forged parts for their excellent corrosion resistance and strength.

- Shipbuilding Components

Anchor Chains: Forged anchor chains provide the necessary strength to secure large vessels.

Propeller Shafts: These components require high strength and corrosion resistance to operate effectively in marine environments.

- Offshore Equipment

Drill Rigs: Forged parts in offshore drilling rigs ensure durability and reliability under extreme conditions.

Subsea Connectors: These connectors need to be leak-proof and corrosion-resistant, making forging an ideal choice.

Hot forging is a critical manufacturing process that provides high strength, durability, and precision to components used in various industries. From automotive and aerospace to heavy industry and marine applications, hot forging ensures that parts can withstand demanding conditions and meet rigorous performance standards. The versatility and reliability of hot-forged components make them indispensable in modern industrial applications.

Let's Start Project!

We will give you a quick reply and quote within 12 hours.

- Phone: 0086-18779223927

- Email: Lynnyao@prototekparts.com

- Address: Nanchang,Jiangxi,China