Blog Details

The Ultimate Knowledge of Stainless Steel Machining Parts

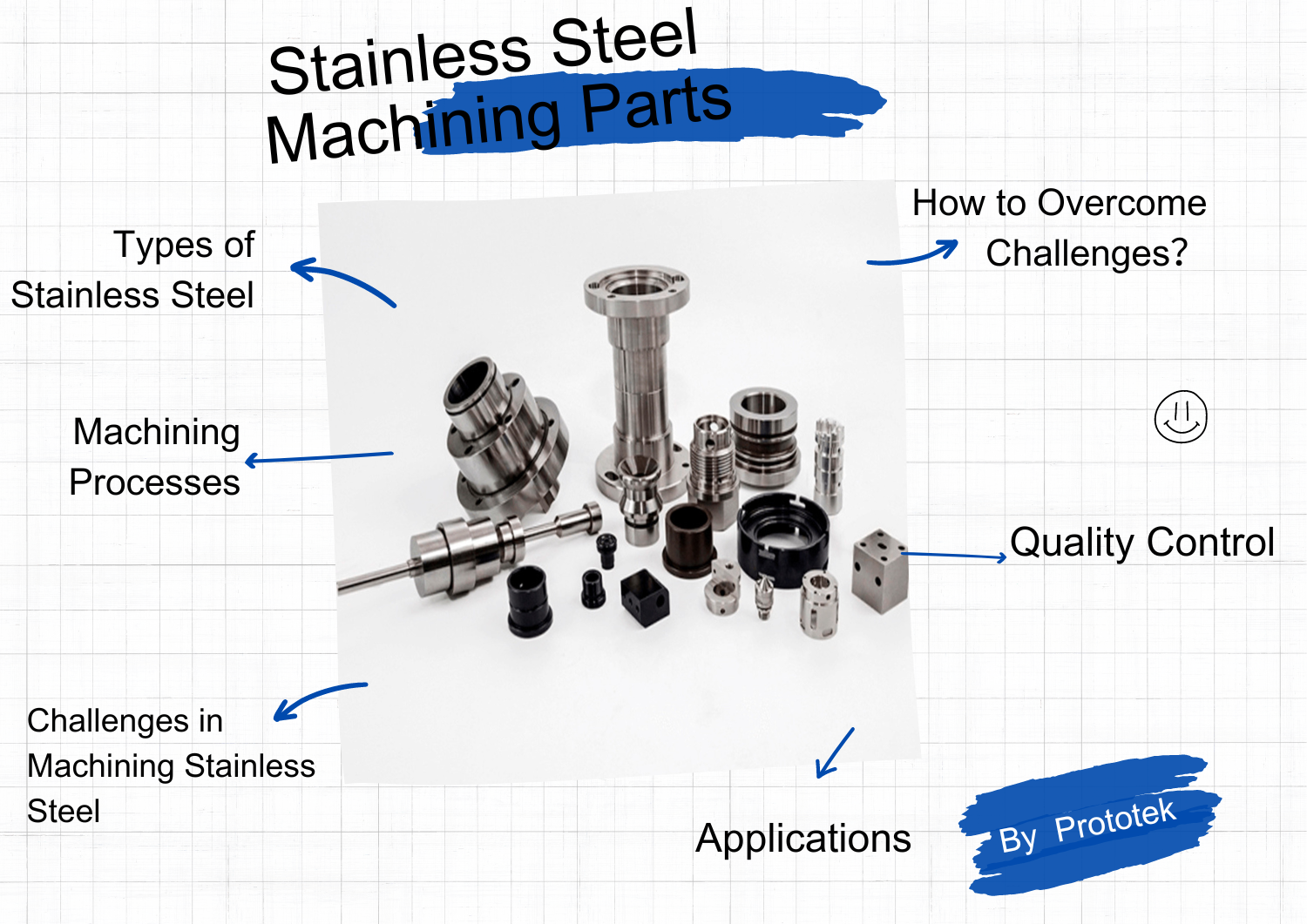

Stainless steel machining parts are essential for various industries due to their durability, corrosion resistance, and aesthetic appeal. These parts are crafted using various machining processes, ensuring they meet the precise specifications required for different applications. Understanding the types of stainless steel used, the machining processes, and the challenges involved can help you make informed decisions about using stainless steel for your projects.

Types of Stainless Steel Used in Machining

Stainless steel comes in various grades, each offering unique properties suitable for different applications and machining processes. Understanding the characteristics of these grades can help select the right type of stainless steel for specific needs.

304 Stainless Steel

Properties and Advantages

- Composition: Contains 18% chromium and 8% nickel, making it an austenitic stainless steel.

- Corrosion Resistance: High resistance to corrosion, particularly against various acids found in food processing environments.

- Weldability: Excellent weldability without the need for post-weld annealing.

- Formability: Good formability, making it easy to shape and fabricate.

- Temperature Tolerance: Performs well in both high and low temperatures.

Typical Uses

- Food Processing Equipment: Due to its resistance to corrosion and ease of cleaning, it is widely used in kitchen sinks, countertops, and brewing equipment.

- Chemical Containers: Suitable for storing chemicals that are not highly corrosive.

- Architectural Applications: Used in exterior accents and structures due to its aesthetic appeal and durability.

316 Stainless Steel

Properties and Advantages

- Composition: Contains 16% chromium, 10% nickel, and 2% molybdenum, which enhances its corrosion resistance.

- Enhanced Corrosion Resistance: Superior resistance to chlorides and industrial solvents, making it ideal for harsh environments.

- Strength and Durability: Maintains strength and toughness at both high and low temperatures.

- Weldability and Fabrication: Similar to 304, it has good weldability and is easy to fabricate.

Typical Uses

- Marine Applications: Often used in marine environments due to its resistance to saltwater corrosion.

- Medical Devices: Common in surgical instruments and implants because of its biocompatibility.

- Chemical Processing: Used in equipment that handles corrosive chemicals.

410 Stainless Steel

Properties and Advantages

- Composition: Contains 11.5% to 13.5% chromium, making it a martensitic stainless steel.

- High Strength: Known for its high mechanical strength and hardness.

- Heat Treatment: Can be heat treated to achieve a wide range of hardness and mechanical properties.

- Moderate Corrosion Resistance: Provides adequate resistance to corrosion for many applications.

Typical Uses

- Cutlery and Tools: Used in the production of knives and cutting tools due to its hardness.

- Surgical Instruments: Suitable for certain surgical instruments that require high strength.

- Valves and Pumps: Used in manufacturing parts that require both strength and moderate corrosion resistance.

416 Stainless Steel

Properties and Advantages

- Composition: Contains 12-14% chromium and added sulfur, making it a free-machining variation of 410.

- Machinability: Enhanced machinability due to the addition of sulfur, which improves chip breaking.

- High Strength: Retains the high strength and hardness characteristics of 410.

- Corrosion Resistance: Similar to 410, with adequate resistance for many applications.

Typical Uses

- Fasteners: Commonly used in screws, bolts, and other fasteners that require precise machining.

- Gears: Ideal for gears and shafts due to its machinability and strength.

- Automotive Components: Used in various automotive parts where machinability and moderate corrosion resistance are needed.

Comparison of Different Grades

Each grade of stainless steel offers distinct properties, making them suitable for different machining and application requirements:

- 304 vs. 316: While both are austenitic and highly corrosion-resistant, 316 offers superior resistance to chlorides and harsh chemicals due to adding molybdenum. This makes 316 more suitable for marine and medical applications.

- 410 vs. 416: Both are martensitic and offer high strength, but 416’s enhanced machinability makes it preferable for parts requiring intricate machining. However, it has slightly lower corrosion resistance compared to 410.

- Overall: The choice between these grades depends on factors such as corrosion resistance requirements, strength, machinability, and the specific environmental conditions the parts will be exposed to.

Machining Processes for Stainless Steel Parts

Machining stainless steel involves various techniques that shape and form the material to meet specific design and functional requirements. Each process offers distinct advantages and is chosen based on the desired outcome of the machined parts.

Turning

Turning is a machining process where a cutting tool removes material from a rotating stainless steel workpiece. This process is typically performed on a lathe, which creates cylindrical parts.

Process Details

- Lathe Setup: The workpiece is secured in a chuck and rotated at high speed.

- Tool Movement: A cutting tool moves linearly along the axis of rotation to remove material.

- Precision: Allows for high precision and smooth finishes.

Applications

- Shafts and Rods: Commonly used for producing shafts, rods, and other cylindrical components.

- Threaded Parts: Ideal for creating threads on screws, bolts, and other fasteners.

Milling

Milling involves using rotary cutters to remove material from a stationary workpiece. This versatile process can produce a wide range of shapes and features.

Process Details

- Milling Machines: Utilizes either horizontal or vertical milling machines.

- Cutting Tools: Employs various cutting tools such as end mills, face mills, and ball nose cutters.

- Movement: The workpiece can move along multiple axes to achieve the desired shape.

Applications

- Complex Shapes: Suitable for parts with complex geometries, slots, holes, and pockets.

- Flat Surfaces: Often used to create flat surfaces, grooves, and intricate patterns.

Drilling

Drilling creates holes in stainless steel parts using rotary cutting tools called drill bits.

Process Details

- Drill Press: Performed using a drill press or a CNC machine.

- Drill Bits: Various drill bits, such as twist and center drills, are used.

- Coolant Use: Coolants are often applied to reduce heat and improve tool life.

Applications

- Fastener Holes: Commonly used for creating holes for screws, bolts, and other fasteners.

- Fluid Passages: Essential for parts requiring precise fluid or gas passages.

Grinding

Grinding uses abrasive wheels to achieve high surface quality and precise dimensions on stainless steel parts.

Process Details

- Abrasive Wheels: Different abrasive wheels, such as grinding wheels and belts, are used.

- Surface Finish: Capable of achieving very fine surface finishes.

- Precision: Provides high dimensional accuracy and smooth surfaces.

Applications

- Surface Finishing: Often used as a finishing process to achieve the desired surface quality.

- Precision Parts: Suitable for parts requiring tight tolerances and high precision.

CNC-bewerking

CNC (Computer Numerical Control) machining utilizes computer-controlled machines to perform various machining operations with high precision and repeatability.

Process Details

- Automated Control: CNC machines are programmed with CAD/CAM software to control the movement of tools.

- Multiple Operations: Can perform turning, milling, drilling, and other operations in a single setup.

- High Efficiency: Offers high efficiency, consistency, and reduced production times.

Applications

- Complex Parts: Ideal for producing complex and intricate stainless steel parts with high accuracy.

- Prototyping and Production: Suitable for both prototyping and high-volume production runs.

Laser Cutting

Laser cutting uses a focused laser beam to melt or vaporize material, creating precise cuts in stainless steel.

Process Details

- Laser Source: Utilizes CO2 or fiber lasers to cut through the material.

- Precision and Speed: Offers high precision and fast cutting speeds.

- Minimal Heat Affected Zone: Reduces thermal distortion and maintains material properties.

Applications

- Intricate Designs: Perfect for cutting intricate designs and patterns in thin stainless steel sheets.

- Custom Shapes: Used for creating custom shapes and parts with complex geometries.

Waterjet Cutting

Waterjet cutting employs a high-pressure jet of water mixed with abrasive particles to cut stainless steel.

Process Details

- High Pressure: Water is pressurized to extreme levels and mixed with abrasive materials.

- Cold Cutting: As a cold cutting process, it eliminates heat-affected zones.

- Veelzijdigheid: Capable of cutting various thicknesses and materials.

Applications

- Thick Materials: Suitable for cutting thick stainless steel plates.

- Complex Shapes: Used for parts requiring intricate cuts and minimal material distortion.

Electrical Discharge Machining (EDM)

EDM uses electrical discharges (sparks) to erode material from the workpiece, allowing for precise machining of hard materials.

Process Details

- Electrical Discharge: An electrode discharges sparks that erode the material.

- No Contact: There is no direct contact between the tool and the workpiece, reducing mechanical stress.

- Fine Tolerances: Capable of achieving fine tolerances and detailed features.

Applications

- Hard Materials: Ideal for machining hard stainless steel grades.

- Complex Geometries: Used for parts with complex shapes and fine details.

By understanding these machining processes and their specific applications, manufacturers can choose the most appropriate methods to achieve the desired results for stainless steel parts. Each process offers unique advantages that cater to different requirements, ensuring high quality and precision in the final products.

Challenges in Machining Stainless Steel

Machining stainless steel presents several challenges due to its unique properties, such as high strength, toughness, and corrosion resistance. Addressing these challenges is crucial for achieving high-quality finishes and maintaining tool life. Below are the primary challenges faced during stainless steel machining and strategies to overcome them.

Work Hardening

Description

- Definition: Work hardening occurs when the stainless steel surface becomes harder and deformed during machining. This makes subsequent cutting operations more difficult and increases tool wear.

- Causes: Excessive heat generation, high cutting speeds, and improper tool angles can contribute to work hardening.

Mitigation Strategies

- Sharp Cutting Tools: Use sharp, high-quality cutting tools to minimize the deformation of the material.

- Proper Feed Rates: Employ appropriate feed rates to reduce heat build-up and prevent surface hardening.

- Coolants and Lubricants: Utilize coolants and lubricants to reduce heat generation and keep the workpiece temperature low.

Tool Wear and Tear

Description

- High Tool Wear: Stainless steel’s hardness and abrasiveness can lead to rapid tool wear, reducing tool life and increasing the need for frequent tool changes.

- Tool Material: The choice of tool material significantly impacts wear resistance and cutting performance.

Mitigation Strategies

- Carbide Tools: Carbide tools offer better wear resistance than high-speed steel (HSS) tools.

- Coated Tools: Implement coated tools (e.g., TiN, TiAlN) that provide an extra layer of protection and reduce friction.

- Regular Maintenance: Schedule regular maintenance and inspections of tools to ensure they remain sharp and in good condition.

Heat Management

Description

- Heat Generation: Machining stainless steel generates significant heat due to its low thermal conductivity. Excessive heat can affect material properties and tool life.

- Thermal Expansion: Heat can cause thermal expansion, leading to dimensional inaccuracies and potential warping of the workpiece.

Mitigation Strategies

- Coolants: Apply coolants generously to dissipate heat and maintain a stable workpiece temperature.

- Cutting Speeds: Optimize cutting speeds to balance efficient material removal with minimal heat generation.

- Intermittent Cutting: Use intermittent cutting techniques (e.g., peck drilling) to allow time for heat dissipation between cuts.

Surface Finish Issues

Description

- Rough Surfaces: Achieving a smooth surface finish on stainless steel can be challenging due to its tendency to work hard and its high strength.

- Burr Formation: The toughness of stainless steel can result in burr formation, requiring additional finishing operations.

Mitigation Strategies

- Fine-Tuned Machining Parameters: Adjust machining parameters, including cutting speed, feed rate, and depth of cut, to achieve the desired surface finish.

- Proper Tool Geometry: Use tools with appropriate geometries designed to minimize surface roughness.

- Finishing Operations: To achieve the required surface quality, employ secondary finishing operations, such as grinding or polishing.

Chip Formation and Removal

Description

- Chip Control: Stainless steel tends to form long, stringy chips that can entangle around the tool and workpiece, causing machining interruptions and potential damage.

- Chip Disposal: Effective chip disposal is essential for smooth machining operations and tool performance.

Mitigation Strategies

- Chip Breakers: Use tools with chip breaker designs to promote the formation of shorter, more manageable chips.

- High-Pressure Coolant: Apply high-pressure coolant to break and evacuate chips from the cutting zone.

- Frequent Clearing: Regularly clear chips from the work area to prevent accumulation and potential hazards.

Material Toughness

Description

- High Toughness: Stainless steel’s toughness can make it more resistant to cutting forces, requiring more power and robust equipment.

- Vibration and Chatter: The increased cutting forces can lead to vibrations and chatter, which can affect surface finish and dimensional accuracy.

Mitigation Strategies

- Stable Workholding: Ensure the workpiece is securely clamped to minimize vibrations and movement during machining.

- Rigid Machine Setup: Use machines with high rigidity and stability to withstand the increased forces.

- Damping Techniques: To reduce chatter, use damping techniques, such as vibration-damping materials or components.

Chemical Reactivity

Description

- Tool Material Reaction: Some stainless steel grades can react with certain tool materials, leading to tool wear or chemical degradation.

- Corrosion: Improper handling and storage of stainless steel can result in corrosion, affecting machinability and surface quality.

Mitigation Strategies

- Tool Coatings: Use coated tools that provide a barrier against chemical reactions.

- Proper Storage: Store stainless steel materials in a dry, clean environment to prevent corrosion.

- Anti-Corrosive Treatments: Apply anti-corrosive treatments or coatings to the workpiece if necessary.

Strategies to Overcome Challenges in Machining Stainless Steel

Overcoming the challenges in machining stainless steel requires advanced techniques, proper tool selection, and optimized machining parameters. Here are detailed strategies to address these challenges effectively:

Mitigating Work Hardening

Work hardening can significantly impact the machinability of stainless steel, making subsequent machining steps more difficult. Strategies to mitigate work hardening include:

- Sharp Cutting Tools:

- Use high-quality, sharp cutting tools to minimize the deformation and work hardening of the material.

- Regularly inspect and replace worn tools to maintain cutting efficiency.

- Appropriate Feed Rates:

- Employ higher feed rates to reduce the amount of heat generated and minimize surface hardening.

- Ensure feed rates are balanced to avoid excessive tool wear.

- Optimal Cutting Conditions:

- Maintain optimal cutting speeds and depths to reduce heat buildup.

- Avoid cutting too slowly, which can increase friction and work hardening.

- Effective Use of Coolants and Lubricants:

- Apply coolants and lubricants to dissipate heat and reduce the likelihood of work hardening.

- Use high-pressure coolant systems to manage temperatures during machining effectively.

Managing Tool Wear and Tear

Tool wear is a significant concern due to the hardness and abrasiveness of stainless steel. Strategies to manage tool wear and prolong tool life include:

- Carbide Tools:

- Carbide tools offer greater wear resistance and durability compared to high-speed steel (HSS) tools.

- Consider advanced carbide grades specifically designed for stainless steel machining.

- Coated Tools:

- Use tools with wear-resistant coatings such as titanium nitride (TiN), titanium carbonitride (TiCN), or aluminum titanium nitride (AlTiN).

- Coated tools reduce friction, enhance heat resistance, and extend tool life.

- Tool Geometry:

- Select tools with appropriate geometries to reduce cutting forces and enhance chip evacuation.

- Opt for positive rake angles to reduce cutting resistance and minimize wear.

- Regular Maintenance and Inspection:

- Implement regular maintenance schedules to inspect and replace tools before significant wear occurs.

- Use tool monitoring systems to detect wear in real time and prevent unexpected tool failures.

Effective Heat Management

Managing heat during machining is crucial to prevent thermal damage and maintain material properties. Strategies include:

- Coolant Application:

- Use coolants generously to dissipate heat and maintain a stable workpiece temperature.

- Implement high-pressure coolant systems for deeper penetration and better heat management.

- Optimized Cutting Speeds:

- Select cutting speeds that balance efficient material removal with minimal heat generation.

- Adjust speeds based on the specific stainless steel grade and machining conditions.

- Intermittent Cutting Techniques:

- Employ peck drilling or interrupted cutting methods to allow heat dissipation between cuts.

- Use multiple passes with lower depths of cut to prevent excessive heat buildup.

- Heat-Resistant Tool Materials:

- Use tools from materials with high thermal conductivity and heat resistance, such as cermets or ceramics.

- Consider advanced tool materials that can withstand higher temperatures without degrading.

Achieving the Desired Surface Finish

Obtaining a smooth surface finish on stainless steel can be challenging. Strategies to improve surface finish include:

- Fine-Tuned Machining Parameters:

- Adjust cutting speeds, feed rates, and depths of cut to achieve the desired surface quality.

- Use lower feed rates and higher cutting speeds for finishing operations.

- Proper Tool Geometry:

- Select tools with geometries designed to minimize surface roughness.

- Use tools with a wiper geometry to improve surface finish in turning operations.

- Finishing Operations:

- Employ secondary finishing processes such as grinding, polishing, or honing to achieve the required surface quality.

- Use abrasive tools with fine grit sizes for better surface finishes.

- Vibration Control:

- Minimize vibrations by ensuring stable work holding and machine setup.

- Use vibration-damping materials or components to reduce chatter and improve surface finish.

Controlling Chip Formation and Removal

Effective chip control is essential to maintain smooth machining operations. Strategies include:

- Chip Breakers:

- Use cutting tools with chip breaker designs to promote shorter, more manageable chips.

- Ensure chip breakers are appropriately designed for the specific machining operation.

- High-Pressure Coolant:

- Apply high-pressure coolant to break and evacuate chips from the cutting zone.

- Use coolant directed at the cutting edge to improve chip control.

- Frequent Clearing:

- Regularly clear chips from the work area to prevent accumulation and potential damage.

- Use air blasts or chip conveyors to remove chips from the machining area.

- Optimized Cutting Conditions:

- Adjust cutting speeds, feed rates, and depths of cut to improve chip breakage and evacuation.

- Balance machining parameters to ensure effective chip control without compromising tool life.

Handling Material Toughness

The toughness of stainless steel requires robust machining setups to handle increased cutting forces. Strategies include:

- Stable Workholding:

- Ensure the workpiece is securely clamped to minimize vibrations and movement during machining.

- Use fixtures and clamps that provide maximum stability.

- Rigid Machine Setup:

- Use machines with high rigidity and stability to withstand increased cutting forces.

- Maintain machine tools and components to ensure optimal performance.

- Damping Techniques:

- To reduce chatter, implement damping techniques, such as vibration-damping materials or components.

- Use tuned mass dampers or passive damping systems to improve machining stability.

- Appropriate Tool Paths:

- Plan tool paths to distribute cutting forces evenly and reduce the risk of deflection or tool breakage.

- Use multi-axis machining techniques to optimize tool engagement and load distribution.

Preventing Chemical Reactivity

Chemical reactivity between the tool material and stainless steel can affect tool life and surface quality. Strategies include:

- Tool Coatings:

- Use coated tools that provide a barrier against chemical reactions.

- Consider coatings such as diamond-like carbon (DLC) for improved chemical resistance.

- Proper Storage and Handling:

- Store stainless steel materials in a dry, clean environment to prevent corrosion.

- Handle materials with care to avoid contamination and corrosion.

- Anti-Corrosive Treatments:

- Apply anti-corrosive treatments or coatings to the workpiece if necessary.

- Use corrosion inhibitors in coolant systems to protect both the tool and workpiece.

Quality Control in Stainless Steel Machining

Ensuring high-quality machined parts is crucial in stainless steel machining. Implementing robust quality control measures throughout the machining process helps maintain precision, accuracy, and consistency in the final products. Here are detailed aspects and strategies for quality control in stainless steel machining:

Inspection and Measurement

Dimensional Accuracy

- Coordinate Measuring Machines (CMM): Utilize CMMs to measure complex geometries and tight tolerances precisely. CMMs can provide accurate data on dimensions, angles, and positions.

- Micrometers and Calipers: Use high-precision micrometers and calipers for measuring smaller features and ensuring dimensional accuracy.

- Laser Scanning: Implement laser scanning technology for non-contact measurement of part dimensions, which is especially useful for intricate shapes.

Surface Finish

- Surface Roughness Testers: Employ surface roughness testers (profilometers) to measure the surface texture and finish. This ensures the machined surface meets the required specifications.

- Visual Inspection: Perform visual inspections under magnification to identify surface defects such as scratches, burrs, or tool marks.

Geometric Tolerances

- Roundness and Flatness Gauges: Use roundness testers and flatness gauges to verify the geometric tolerances of cylindrical and flat surfaces.

- Profile Projectors: Profile projectors inspect the profile of complex parts to ensure they match the design specifications.

Process Control

Tool Condition Monitoring

- Tool Wear Monitoring: Implement tool wear monitoring systems to track cutting tool condition in real-time. This helps in timely replacing worn tools to maintain machining quality.

- Vibration Analysis: Use vibration analysis tools to detect chatter and ensure stable cutting conditions. Minimizing vibrations helps maintain surface finish and dimensional accuracy.

Machining Parameters Optimization

- Statistical Process Control (SPC): Apply SPC techniques to monitor machining processes and identify variations. Use control charts to track key parameters and maintain process stability.

- Adaptive Control Systems: Employ adaptive control systems that automatically adjust machining parameters based on real-time feedback to optimize cutting conditions and maintain quality.

Coolant and Lubrication Management

- Coolant Quality Monitoring: Regularly test coolant for contamination, concentration, and pH levels. Proper coolant management helps maintain consistent machining performance and surface finish.

- Lubrication Systems: Ensure lubrication systems function correctly to reduce friction, heat, and wear during machining.

Material and Component Traceability

Material Certification

- Material Certificates: Obtain material certificates from suppliers to verify the composition and properties of the machined stainless steel. This ensures the material meets the required standards and specifications.

- Traceability Records: Maintain traceability records for each batch of material used. This includes documentation of the material grade, heat number, and supplier information.

Component Tracking

- Serial Numbering: Assign unique serial numbers to each machined part for tracking and identification. This facilitates traceability and quality control throughout the production process.

- Batch Tracking: Implement batch tracking systems to monitor the production history and quality control status of each batch of parts.

Quality Assurance Procedures

First Article Inspection (FAI)

- Initial Validation: Conduct first article inspections to validate the machining process and ensure the first part produced meets all specifications and tolerances.

- Detailed Reporting: Generate detailed inspection reports documenting the measurements, material properties, and any deviations from the design.

In-Process Inspection

- Regular Checks: Perform regular in-process inspections to monitor part quality during machining. This includes checking critical dimensions and surface finish at various stages.

- Process Adjustments: Make necessary adjustments to the machining parameters based on in-process inspection results to maintain quality.

Final Inspection

- Comprehensive Testing: Conduct final inspections of completed parts to ensure they meet all design and quality requirements. This includes dimensional checks, surface finish evaluation, and geometric tolerances.

- Non-Destructive Testing (NDT): Use NDT methods such as ultrasonic testing, magnetic particle inspection, or dye penetrant inspection to detect internal or surface defects without damaging the part.

Documentation and Reporting

Inspection Reports

- Detailed Records: Maintain detailed inspection reports for each machined part, documenting all measurements, test results, and any deviations. These reports provide a traceable record of quality.

- Quality Certificates: Issue quality certificates for parts that meet all specifications, ensuring customers receive documented assurance of part quality.

Continuous Improvement

- Feedback Loops: Implement feedback loops to gather data from inspection reports and customer feedback. Use this information to identify areas for improvement in the machining process.

- Root Cause Analysis: Conduct root cause analysis for any defects or quality issues identified. Implement corrective actions to prevent recurrence and improve overall process quality.

Applications of Machined Stainless Steel Parts

Machined stainless steel parts are integral to various industries due to their excellent properties, such as corrosion resistance, high strength, durability, and aesthetic appeal. Here are detailed descriptions of the key applications of machined stainless steel parts across various sectors:

Ruimtevaartindustrie

The aerospace industry relies heavily on machined stainless steel parts for their strength, lightweight properties, and resistance to extreme conditions.

Components and Applications

- Engine Components: Stainless steel is used in turbine blades, compressor discs, and other critical engine parts that withstand high temperatures and stresses.

- Structural Components: Stainless steel airframes, landing gear, and fasteners provide strength and corrosion resistance for safe and durable aircraft structures.

- Fuel and Hydraulic Systems: Stainless steel tubing and fittings are essential for fuel lines, hydraulic systems, and fluid transfer applications, where leak resistance and durability are crucial.

Automobielindustrie

In the automotive industry, machined stainless steel parts contribute to vehicle performance, safety, and longevity.

Components and Applications

- Exhaust Systems: Stainless steel is commonly used for exhaust manifolds, mufflers, and catalytic converters due to its ability to withstand high temperatures and resist corrosion.

- Engine Parts: Stainless steel’s strength and resistance to wear benefit components such as valves, fuel injectors, and turbochargers.

- Suspension and Chassis: Stainless steel is used in suspension components, brackets, and chassis parts for durability and resistance to road conditions and weather exposure.

Medical and Dental Devices

The medical and dental industries utilize machined stainless steel parts for their biocompatibility, hygiene, and precision.

Components and Applications

- Surgical Instruments: Stainless steel scales, forceps, and scissors offer the necessary sharpness, strength, and stabilizability for surgical procedures.

- Implants: Orthopedic, dental, and prosthetic implants are often made from stainless steel alloys due to their compatibility with the human body and resistance to corrosion.

- Diagnostic Equipment: Stainless steel is used in components for MRI machines, X-ray machines, and other diagnostic equipment, where cleanliness and durability are essential.

Oil and Gas Industry

The oil and gas industry demands machined stainless steel parts that endure harsh environments and high pressures.

Components and Applications

- Pipelines and Fittings: Stainless steel pipelines, valves, and fittings are used for transporting oil and gas, providing resistance to corrosion and high-pressure capabilities.

- Downhole Tools: Tools used in drilling and extraction, such as drill bits, casing, and tubing, benefit from stainless steel’s toughness and wear resistance.

- Refinery Equipment: Stainless steel heat exchangers, pressure vessels, and storage tanks ensure safety and reliability in processing and refining operations.

Food and Beverage Industry

Machined stainless steel parts are essential for maintaining hygiene, durability, and safety in the food and beverage industry.

Components and Applications

- Processing Equipment: Stainless steel mixers, conveyors, and pumps are used in food processing plants because they are easy to clean and resistant to corrosion and contamination.

- Storage and Handling: Stainless steel tanks, containers, and piping systems ensure the safe storage and handling of food and beverages without risk of contamination.

- Kitchen Appliances: Commercial kitchen equipment, such as ovens, grills, and refrigeration units, utilize stainless steel for its durability, cleanliness, and aesthetic appeal.

Marine Industry

The marine industry benefits from stainless steel’s excellent corrosion resistance, especially in saltwater environments.

Components and Applications

- Boat Hardware: Stainless steel is used in anchors, cleats, railings, and fittings due to its ability to resist corrosion from seawater and marine conditions.

- Propulsion Systems: Stainless steel propellers, shafts, and engine components provide the necessary strength and durability for marine propulsion systems.

- Marine Structures: Stainless steel is used in offshore platforms, pipelines, and other marine structures for its long-term resistance to corrosion and harsh marine environments.

Construction Industry

In the construction industry, machined stainless steel parts contribute to building and infrastructure’s structural integrity and aesthetic appeal.

Components and Applications

- Architectural Elements: Stainless steel is used in facades, handrails, and cladding for its modern look and resistance to weathering and corrosion.

- Structural Components: Beams, columns, and fasteners made from stainless steel provide strength and durability in construction projects.

- HVAC Systems: Stainless steel ductwork, fans, and heat exchangers are used in HVAC systems for their longevity and resistance to corrosion.

Electronics Industry

The electronics industry employs machined stainless steel parts for their precision, reliability, and conductivity.

Components and Applications

- Enclosures and Housings: Stainless steel enclosures protect sensitive electronic components from environmental factors and electromagnetic interference.

- Connectors and Terminals: Stainless steel connectors and terminals provide reliable electrical connections with resistance to corrosion and wear.

- Heat Sinks: Stainless steel heat sinks dissipate heat in electronic devices, ensuring their efficient operation and longevity.

Renewable Energy Industry

The renewable energy sector utilizes machined stainless steel parts for their robustness and resistance to environmental factors.

Components and Applications

- Wind Turbine Components: Stainless steel is used in wind turbine blades, shafts, and fasteners because it is strong and resistant to fatigue.

- Solar Panel Frames: Stainless steel frames provide durability and corrosion resistance for solar panels exposed to the elements.

- Hydropower Systems: Stainless steel’s resistance to corrosion and wear benefits turbines, valves, and other components in hydropower systems.

Consumer Goods

Machined stainless steel parts are also prevalent in various consumer goods, enhancing their durability and aesthetic appeal.

Components and Applications

- Household Appliances: Stainless steel is used in appliances such as refrigerators, dishwashers, and washing machines for its sleek appearance and resistance to rust and stains.

- Cutlery and Cookware: Stainless steel cutlery, pots, and pans are popular for their durability, hygiene, and ease of cleaning.

- Personal Items: Watches, jewelry, and eyewear frames made from stainless steel offer strength, corrosion resistance, and a polished look.

Advantages of Using Stainless Steel for Machined Parts

Stainless steel offers numerous advantages, including corrosion resistance, strength, durability, aesthetic appeal, hygienic properties, and recyclability.

Advances in machining technology, emerging materials, sustainability efforts, and market trends are shaping the future of stainless steel machining.

Choosing the Right Supplier for Stainless Steel Machining Parts

When choosing a supplier for stainless steel machining parts, consider the supplier’s experience, quality assurance, delivery times, and cost; Prototek is a good choice for you to choose the supplier.

Due to their exceptional properties, stainless steel machining parts play a vital role in various industries. By understanding the different grades of stainless steel, machining processes, and quality control measures, you can make informed decisions and leverage the benefits of stainless steel for your projects.

Neem contact met ons op via e-mail op Lynnyao@prototekparts.com of bel: +86-0792-86372550

Tags:

- metal stamping