What is Cold Forging

Cold forging, a cornerstone of modern manufacturing, embodies precision and efficiency in shaping metals. Differing from its hot forging counterpart, cold forging utilizes ambient temperatures to shape complex forms with remarkable accuracy and surface finish resemblance. This post delves into the principles; advantages, materials used, surface treatments, and diverse cold forging applications.

How cold forging works?

Cold forging works by shaping metal at room temperature or slightly above using compressive forces applied through dies and punches. Here’s a detailed explanation of how the process works:

Material Preparation

Raw material, typically in the form of bar stock or wire, is cut to the required length.

The material may undergo pre-treatment steps such as cleaning and lubrication to facilitate smooth deformation.

BAR STOCK

WIRE

Die Design and Setup

Cold forging requires specialized dies that define the shape and dimensions of the final part.

Dies are designed to withstand high pressures and are typically made from tough materials like tool steel.

The die cavity matches the desired shape of the finished part, and it includes features to allow for material flow and removal of excess metal (flash).

Forming Operating

The prepared material is placed into the die cavity.

A punch exerts compressive force on the material, causing it to flow and take the shape of the die cavity.

The material undergoes plastic deformation, meaning it changes shape permanently without fracturing.

The force applied by the punch is carefully controlled to ensure optimal material flow and to prevent defects.

Material Flow and Deformation

As the punch applies force, the metal undergoes deformation through processes such as extrusion, upsetting, bending, or coining, depending on the shape of the die.

The metal grains within the material reorient and align according to the direction of force, contributing to improved mechanical properties.

Flash Formation and Removal

During forging, excess metal (flash) may squeeze out of the die edges.

Post-forming operations include trimming or cutting off this flash to achieve the final shape and dimensions of the part.

Finishing Operations

After forging, the part may undergo additional finishing operations such as heat treatment, machining, or surface treatment to enhance properties like hardness, strength, or corrosion resistance.

heat treatment

machining

surface treatment

Characteristics of Cold Forging

Cold forging is a specialized metal forming process known for its ability to shape metals at room temperature or slightly above using compressive forces. This method offers several distinctive characteristics that set it apart from other manufacturing techniques:

Vantagens

1.High Precision:

Cold forging enables the production of parts with tight tolerances and intricate geometries. The process involves precise control over die dimensions, punch forces, and material flow, resulting in finished components that often require minimal additional machining.

2.Superior Surface Finish:

Compared to hot forging or other metal forming methods, cold forging typically produces parts with excellent surface smoothness and finish. The absence of high temperatures reduces oxidation and scale formation on the metal surface, eliminating or minimizing the need for secondary finishing processes like grinding or polishing.

3.Material Savings:

Cold forging process involves precise shaping of the metal without significant material loss, which is beneficial for expensive materials or when minimizing waste is a priority. Manufacturers can optimize material usage by designing dies and processes that minimize scrap generation, contributing to cost-effectiveness and sustainability in production.

4.Enhanced Mechanical Properties:

Cold forging enables the production of parts with tight tolerances and intricate geometries. The process involves precise control over die dimensions, punch forces, and material flow, resulting in finished components that often require minimal additional machining.

5.Design Flexibility:

Cold forging allows for the production of complex shapes and configurations. The versatility of cold forging dies enables the creation of various part geometries, including asymmetrical and multi-dimensional forms, thereby expanding design possibilities for engineers and designers.

6.Cost-Effectiveness:

Despite requiring specialized equipment and tooling, cold forging offers long-term cost benefits due to reduced material waste, lower energy consumption (compared to hot forging), and the elimination of machining for dimensional accuracy and surface finish.

7.Environmental Benefits:

Cold forging aligns with sustainable manufacturing practices by minimizing material waste, reducing energy consumption, and lowering carbon emissions associated with heat-intensive processes. The process is more environmentally friendly.

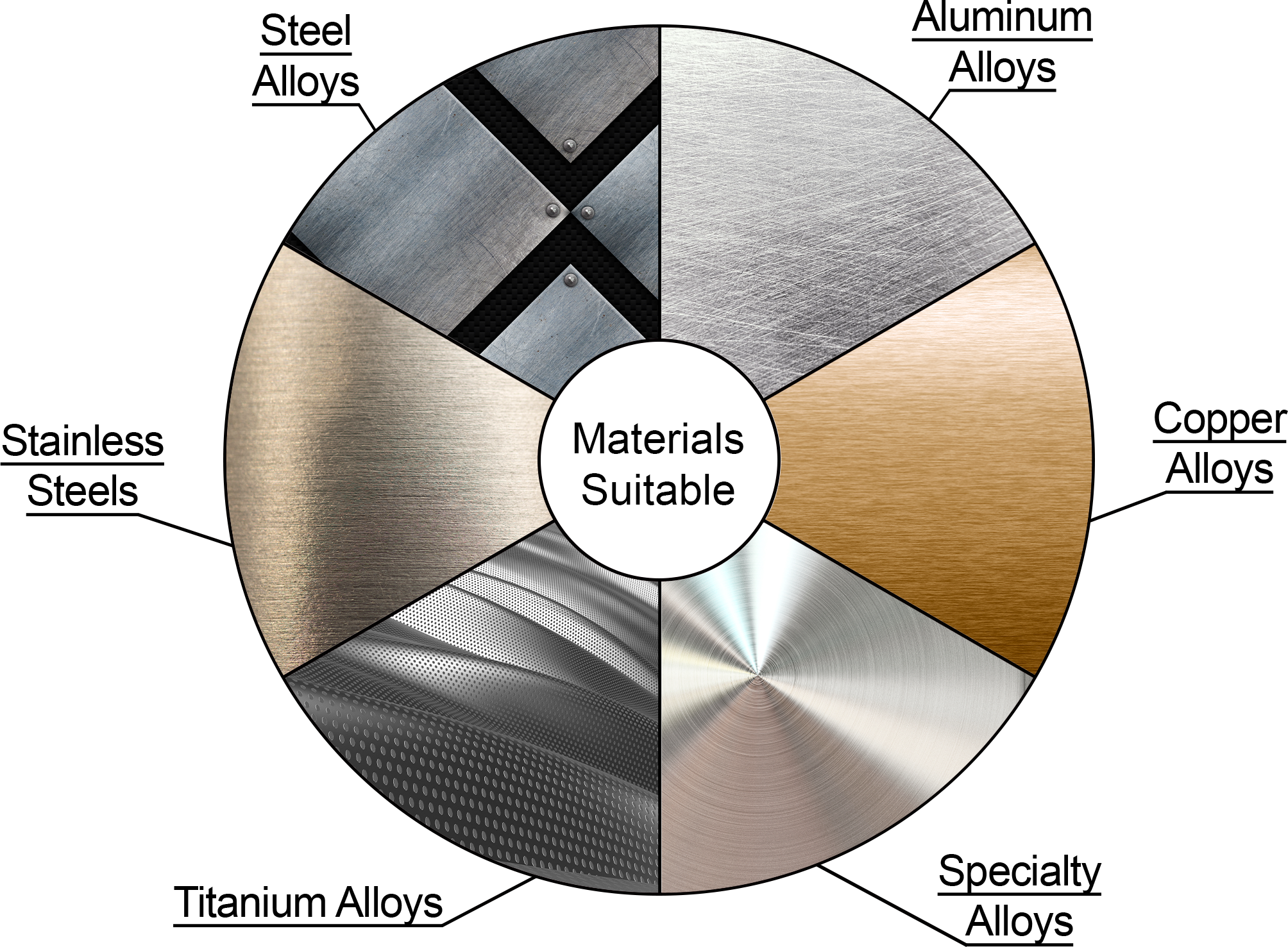

Materials Suitable for Cold Forging

Cold forging is compatible with a variety of metals and alloys, each selected based on its specific mechanical properties, formability characteristics, and intended application. Here’s a detailed exploration of materials commonly used in cold forging:

Carbon Steel (e.g., AISI 1018, 1045):

Properties: High strength, good machinability, and moderate ductility.

Applications: Fasteners, shafts, automotive components.

Alloy Steels (e.g., AISI 4140, 4340):

Properties: Enhanced hardness, toughness, and wear resistance due to alloying elements (chromium, molybdenum).

Applications: Gears, crankshafts, structural components.

6061-T6 Aluminum Alloy:

Properties: Lightweight, corrosion-resistant, good mechanical properties post-forging.

Applications: Aerospace components, automotive parts, electronic housings.

7075-T6 Aluminum Alloy:

Properties: High strength, excellent machinability, and stress corrosion resistance.

Applications: Aircraft structures, high-strength parts.

Copper Beryllium (e.g., C17200):

Properties: High strength, conductivity, and wear resistance.

Applications: Electrical connectors, springs, bearings.

Brass (e.g., C36000):

Properties: Good machinability, corrosion resistance, and aesthetic appeal.

Applications: Plumbing fittings, decorative hardware, electrical components.

Austenitic Stainless Steels (e.g., AISI 304, 316):

Properties: Excellent corrosion resistance, high ductility, and strength.

Applications: Food processing equipment, marine hardware, medical instruments.

Duplex Stainless Steels (e.g., UNS S31803):

Properties: Combination of high strength and corrosion resistance.

Applications: Oil and gas industry components, structural parts.

Ti-6Al-4V Titanium Alloy:

Properties: High strength-to-weight ratio, excellent corrosion resistance, biocompatibility.

Applications: Aerospace structures, medical implants, sports equipment.

Nickel-Based Alloys (e.g., Inconel 718):

Properties: High temperature resistance, excellent mechanical properties at elevated temperatures.

Applications: Gas turbines, aerospace components, chemical processing equipment.

Selection Criteria for Cold Forging Materials

Formability:

Materials must exhibit good flexibility and deformability at room temperature to undergo the plastic deformation required in cold forging without cracking or excessive strain.

Mechanical Properties:

Materials must exhibit good ductility and deformability at room temperature to undergo the plastic deformation required in cold forging without cracking or excessive strain.

Surface Finish:

Ability to achieve desired surface quality and finish without extensive post-processing.

Cost Considerations:

Balance between material cost, performance requirements, and overall production economics.

The choice of material for cold forging depends on the specific requirements of the component being produced, ranging from mechanical properties to environmental conditions and regulatory standards. Advances in material science and cold forging techniques continue to expand the range of materials suitable for this precision manufacturing process, enabling industries to produce complex, high-performance parts efficiently and cost-effectively.

Surface Treatment of Cold Forged Components

Surface treatment plays a crucial role in enhancing the functional and aesthetic properties of cold-forged components. It helps improve corrosion resistance, wear resistance, and overall durability while also providing opportunities for achieving specific aesthetic requirements. Here’s a detailed exploration of common surface treatment methods used in cold forging:

1. Electroplating

Process: Electroplating involves depositing a thin layer of metal onto the surface of a substrate using an electrolytic process. The substrate (cold-forged component) acts as the cathode in an electrolytic cell, while the metal to be plated acts as the anode.

Materials: Common metals used for electroplating include zinc (for corrosion protection), nickel (for wear resistance and aesthetics), chrome (for decorative finish), and various alloys.

Applications: It is common in the automotive, plumbing, and hardware industries.

2. Coatings

Organic Coatings: Polymer coatings such as epoxy or polyurethane for corrosion protection and aesthetic purposes.

Inorganic Coatings: Phosphate coatings for enhancing paint adhesion or improving corrosion resistance.

Applications: Coatings are applied to cold forged components where specific functional properties are required, such as in the automotive and aerospace industries for enhancing durability and performance under harsh conditions.

3. Heat Treatment

Purpose: Heat treatment processes such as annealing, tempering, or case hardening modify their mechanical properties, including hardness, toughness, and residual stresses.

Process: Components are heated to specific temperatures and then cooled in a controlled manner to achieve desired microstructural changes.

Applications: Heat treatment is critical for optimizing the performance of cold-forged parts in terms of strength, hardness, and dimensional stability. It is commonly used in the automotive, aerospace, and tooling industries.

4. Surface Mechanical Treatments

Shot Peening: Involves bombarding the surface of components with high-velocity abrasive particles (shots) to induce compressive stresses, thereby increasing fatigue life and resistance to stress corrosion cracking.

Polishing and Grinding: Mechanical processes used to achieve desired surface finish and dimensional accuracy post-cold forging.

Applications: Surface mechanical treatments are essential for improving fatigue resistance, enhancing surface finish, and achieving precise dimensional tolerances in cold forged components used in automotive, aerospace, and medical industries.

5. Passivation

Purpose: Passivation involves treating the surface of stainless steel components to remove contaminants and create a passive oxide layer that enhances corrosion resistance.

Process: Typically involves immersion in an acid solution to remove free iron and other surface contaminants, followed by rinsing and drying.

Applications: Passivation is essential for cold-forged stainless steel components used in medical, food processing, and marine applications where corrosion resistance and biocompatibility are critical.

Considerations for Surface Treatment Selection

Functional Requirements: Surface treatments should align with the specific functional requirements of the cold-forged component, such as corrosion resistance, wear resistance, or biocompatibility.

Aesthetic Considerations: Depending on the application, surface treatments may also be chosen to enhance the visual appearance of the component.

Cost and Production Considerations: Surface treatment methods should be chosen considering their cost-effectiveness, impact on production lead times, and compatibility with overall manufacturing processes.

Cold-forged components benefit greatly from surface treatment to optimize their performance, durability, and aesthetics; making them suitable for numerous industrial applications. By selecting suitable surface treatment methods manufacturers can optimize cold forged parts’ functionality and appearance to meet stringent performance requirements and customer expectations across a variety of industries.

Applications of Cold Forged Components

Cold forging finds extensive applications across various industries due to its ability to produce high-strength, precision components with excellent mechanical properties and dimensional accuracy. Here’s an in-depth exploration of its applications in key markets:

Components: Cold forging is widely used to manufacture automotive components such as bolts, nuts, shafts, gears, and suspension parts.

Benefits: The process provides components with high strength, wear resistance, and dimensional accuracy, which are crucial for ensuring reliability and safety in vehicles.

Applications: Found in engines, transmissions, steering systems, braking systems, and chassis components.

2. Aerospace and Defense

Components: Cold forged parts are essential in aerospace applications where lightweight, high-strength materials are required, such as aircraft landing gear, structural components, and engine parts.

Benefits: Offers components with enhanced fatigue resistance, corrosion resistance, and performance under extreme conditions.

Applications: Used in aircraft structures, missile components, satellite systems, and military vehicles.

3. Electronics and Electrical Equipment

Components: Cold forging is employed to manufacture small, precision parts for electronic devices, including connectors, terminals, and heat sinks.

Benefits: Provides parts with high conductivity, dimensional precision, and mechanical strength. It’s critical for reliable performance in electronic systems.

Applications: Found in smartphones, computers, consumer electronics, and industrial control systems.

4. Medical and Healthcare

Components: Cold forging produces high-precision components used in medical devices and equipment, such as surgical instruments, implants, and dental tools.

Benefits: Offers biocompatible materials with excellent surface finish, dimensional accuracy, and mechanical properties required for medical applications.

Applications: Used in orthopedic implants, cardiovascular devices, surgical tools, and diagnostic equipment.

5. Industrial and Machinery

Components: Cold forging is utilized to manufacture various industrial components including fasteners, couplings, bearings, and hydraulic fittings.

Benefits: Provides parts with high load-bearing capacity, durability, and resistance to wear and corrosion.

Applications: Found in machinery, heavy equipment, industrial tools, and manufacturing systems.

6. Consumer Goods

Components: Cold forging produces components for consumer goods such as hardware, hand tools, sporting goods, and appliances.

Benefits: Enhances product durability, functionality, and aesthetic appeal through precise shaping and surface treatments.

Applications: Used in door handles, locks, hinges, bicycle parts, kitchen appliances, and gardening tools.

Advantages in Various Markets

Indústria automotiva

Aeroespacial e Defesa

Consumer Goods

- Precision and Quality: Cold forging ensures parts with tight tolerances, minimal machining requirements, and superior surface finish, meeting stringent industry standards.

- Cost Efficiency: Reduced material waste, lower energy consumption, and minimized post-processing contribute to overall cost savings in manufacturing.

- Performance: Components produced through cold forging exhibit enhanced mechanical properties such as strength, hardness, and toughness, which are suitable for demanding applications.

Cold forging plays an invaluable role across various markets by offering manufacturers cost-effective and efficient ways of producing high-quality components with long lifespans and exceptional quality. Thanks to its versatility in shaping various metals and alloys, industries spanning automotive and aerospace to electronics and medical devices all utilize cold forging as part of their supply chains to meet modern application standards with parts that are long-lasting, reliable parts that meet rigorous demands of modern applications. Cold forging remains at the core of manufacturing innovation worldwide by driving efficiency, sustainability, and excellence in product development globally.

Let's Start Project!

We will give you a quick reply and quote within 12 hours.

- Phone: 0086-18779223927

- Email: Lynnyao@prototekparts.com

- Address: Nanchang,Jiangxi,China