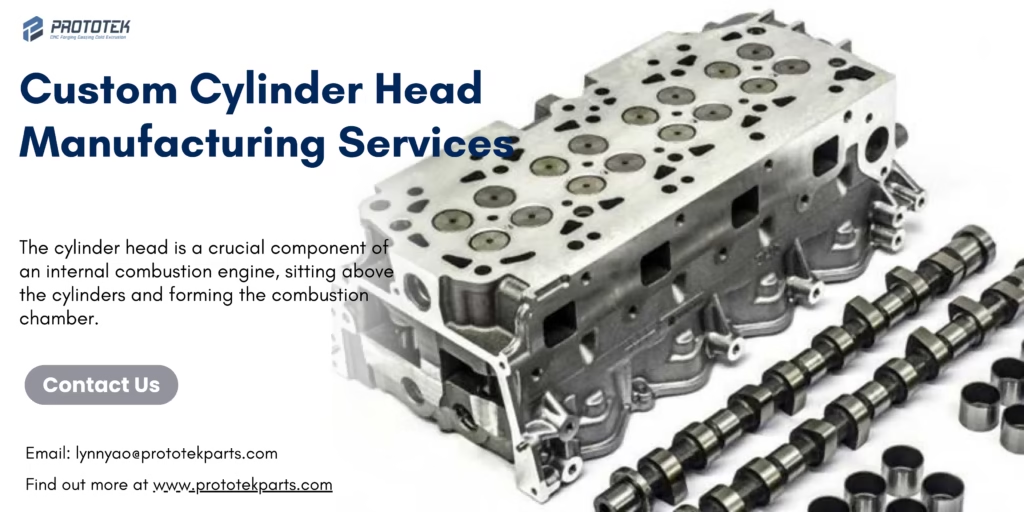

Custom Cylinder Head Manufacturing Services

Custom Cylinder Head Manufacturing Services What is a Cylinder Head? The cylinder head is a crucial component of an internal combustion engine, sitting above the cylinders and forming the combustion chamber. It plays a vital role in controlling airflow in and out of the engine and houses components such as valves, spark plugs, and fuel injectors. How the cylinder head is constructed The cylinder head is not only an important part of the engine, but also one of the most expensive parts of the vehicle engine due to its complex structure. Since the cylinder head is exposed to extremely high temperatures during the combustion process, it is made of high-temperature resistant aluminum alloys and light metals. The bottom of the cylinder head is usually fixed directly to the crankcase, and the top is closed with a valve cover. Depending on whether the vehicle is a diesel engine or a gasoline engine, the structure of the cylinder head will be different. These are the parts of the cylinder head of a gasoline engine Intake and exhaust pipes: ensure that the exhaust gas can be discharged from the cylinder and the absorbed air-fuel mixture can enter the cylinder Intake and exhaust valves: The gasoline engine inhales the air-fuel mixture and at the same time delivers the exhaust gas to the exhaust system Camshaft: The crankshaft, driven by the timing belt, drives the camshaft. The camshaft is responsible for opening and closing the valves Fuel injectors: ensure that the fuel is sprayed into the combustion chamber Spark plugs: They initiate the combustion of the fuel These are the components of the cylinder head of a diesel engine Intake and exhaust pipes: they allow the exhaust gases to exit the cylinders and the trapped air-fuel mixture to enter the cylinders Intake and exhaust valves: Diesel vehicles draw air in through the intake and exhaust valves while sending exhaust gases to the exhaust system Camshaft: The crankshaft, which is driven by the timing chain, drives the camshaft. The camshaft is responsible for opening and closing the valves Fuel injectors: spray the fuel in a diesel engine into the combustion chamber or pre-chamber Glow plugs: they act as a cold-starting aid Functions of Cylinder Heads Sealing the Combustion Chamber– Ensures optimal compression and prevents leakage. Housing Critical Engine Components– Includes intake/exhaust valves, camshafts, and spark plugs. Heat Dissipation– Helps dissipate heat generated during combustion. Optimizing Engine Performance– Directly impacts fuel efficiency, engine power, and emissions. Materials of Cylinder Heads At Prototek, we offer custom cylinder head manufacturing using materials such as: Aluminum Alloys – Lightweight and excellent thermal conductivity. Cast Iron–Durable, ideal for heavy-duty applications. Stainless Steel–High corrosion resistance for specialty applications. Material type Advantages Limitations Applicable scenarios Aluminum Alloys Lightweight, fast heat dissipation Low high temperature strength Passenger cars, aircraft engines Cast Iron High temperature resistance, low cost Heavy weight Commercial vehicles, industrial machinery Key technologies and processes of cylinder heads Multi-axis CNC machining: Five-axis linkage: high-precision machining of complex air passages and combustion chamber contours (case: integral impeller machining technology). Tornado milling: efficient machining of threaded holes and valve guides, reducing tool wear2. Tool selection: Ball-end cylindrical milling cutter: used for surface finishing, reducing surface roughness (Ra≤0.8µm)67. Carbide drill: optimize deep hole machining, avoid thermal deformation3. Process difficulties and solutions: Thermal deformation control: use low-temperature cutting fluid and segmented machining strategy8. Airtightness guarantee: rolling process improves sealing surface hardness (surface hardness increased by 30%) Why Choose Prototek for Your Cylinder Head Projects? Custom Prototyping & Low Volume Production – Ideal for aftermarket and performance auto parts. Strict Quality Control – ISO-certified processes ensure consistent quality. Engineering Support – DFM feedback and fast quoting Fast Lead Time – We ship globally and offer flexible production cycles. If you have any needs, contact us via email at Lynnyao@prototekparts.com or phone: +86-0792-86372550 Tags: Social Network: Recently Posts Online Help! +(86) 0791-86372550 WANT TO DISCUSS IN DETAIL Contact Our Consultant Now CONTACT NOW