Darbeli Ekstrüzyon Alüminyumunu Anlamak

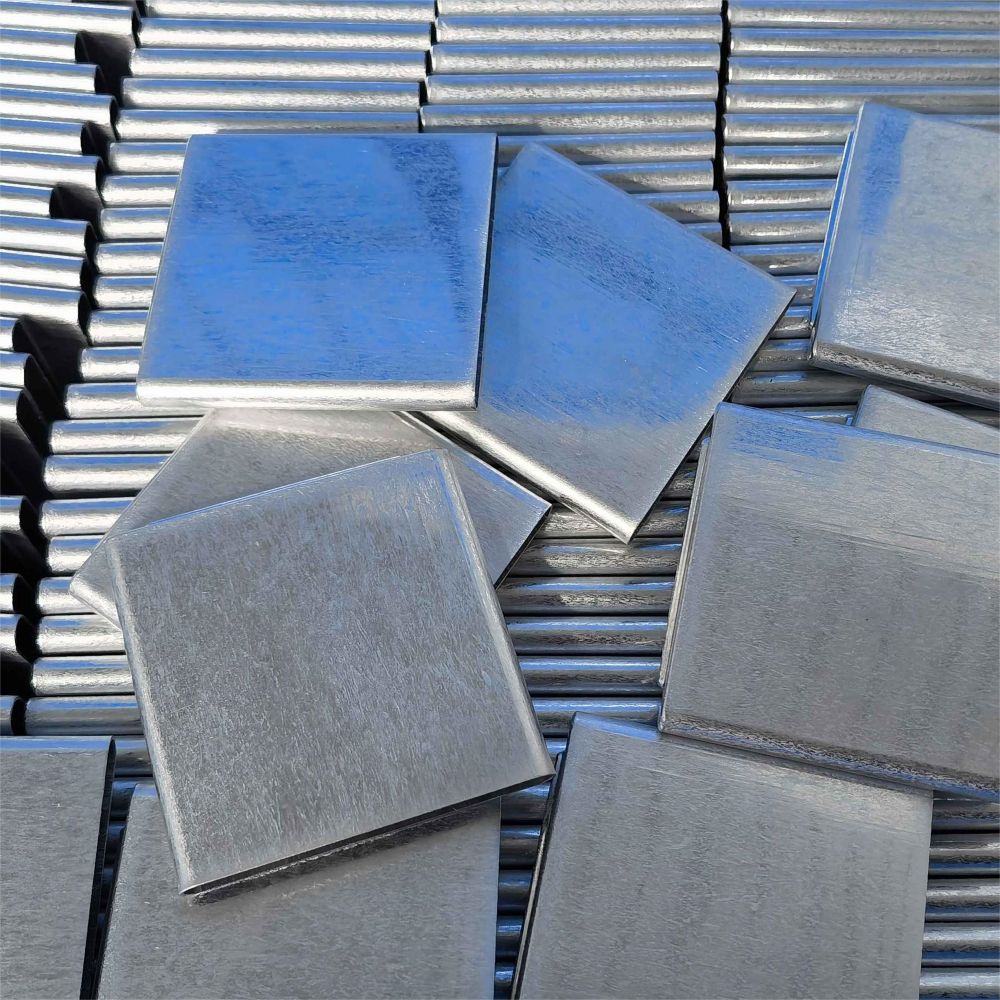

Blog Details Aluminum, renowned for its versatility and lightweight properties, undergoes various manufacturing processes. One increasingly popular and versatile method is Impact Extrusion Aluminum, a technique embraced by Prototek. What is Impact Extrusion Aluminum? Prototek recognizes Impact Extrusion Aluminum as a method involving exerting extreme pressure on aluminum blanks to shape them into precise forms using a die. This controlled deformation process allows for the creation of intricate and accurately designed products, offering a unique manufacturing solution. Applications Across Industries Prototek acknowledges the extensive harnessing of impact extrusion aluminum across industries. In the automotive sector, this method empowers the creation of lightweight yet robust components, enhancing vehicle performance and fuel efficiency. Prototek witnesses its application in engine components and structural elements, benefiting from the material’s exceptional properties. Furthermore, in the packaging industry, Prototek notes the pivotal role of impact extrusion aluminum. It’s instrumental in producing durable containers and packaging solutions that prioritize the safe storage and transportation of food and beverage products. Its corrosion-resistant nature also proves beneficial in pharmaceutical packaging. Moreover, the aerospace sector leverages impact extrusion aluminum for its high-strength and lightweight properties. Prototek acknowledges its contribution to the construction of aircraft components requiring reliability and reduced weight. Why the Popularity? Prototek acknowledges the multifaceted appeal of impact extrusion aluminum. Its lightweight nature significantly reduces overall product weight without compromising strength, making it an ideal choice for industries aiming for improved efficiency and reduced fuel consumption. Furthermore, the cost-effectiveness of the process, coupled with the material’s recyclability, contributes to its popularity. It aligns with sustainability goals, offering an eco-friendly alternative without compromising performance. The Process Unveiled Prototek understands the meticulous process involved in impact extrusion aluminum. Initially, aluminum blanks, typically cylindrical in shape, are precisely prepared. These blanks are then placed in a chamber where extreme pressure is applied, forcing the metal into a die. The result is a precisely formed product, intricately designed as per the die’s specifications. This controlled deformation process ensures the creation of products with high accuracy and intricate detailing, catering to various industry needs. Looking Ahead Prototek acknowledges the role of innovation in driving advancements in impact extrusion aluminum. Current trends emphasize improving process efficiency and exploring new applications. Future developments might witness its integration into previously unexplored industries and the creation of even more intricate shapes with heightened precision. Impact extrusion aluminum exemplifies the ingenuity of manufacturing processes. Its adaptability, cost-efficiency, and environmental sustainability, as recognized by Prototek, position it as a pivotal method across various industries. As technological advancements persist, Prototek anticipates its further integration and expanded applications, solidifying its integral role in modern manufacturing practices. For any inquiries or consultations, please don’t hesitate to contact Prototek. We are committed to providing comprehensive solutions and expertise in impact extrusion aluminum and other innovative manufacturing techniques.If you have any needs, contact us via email: Lynnyao@prototekparts.com or phone: +86-0792-86372550 Tags: Social Network: Recently Posts Online Help! +(86) 0791-86372550 WANT TO DISCUSS IN DETAIL Contact Our Consultant Now CONTACT NOW