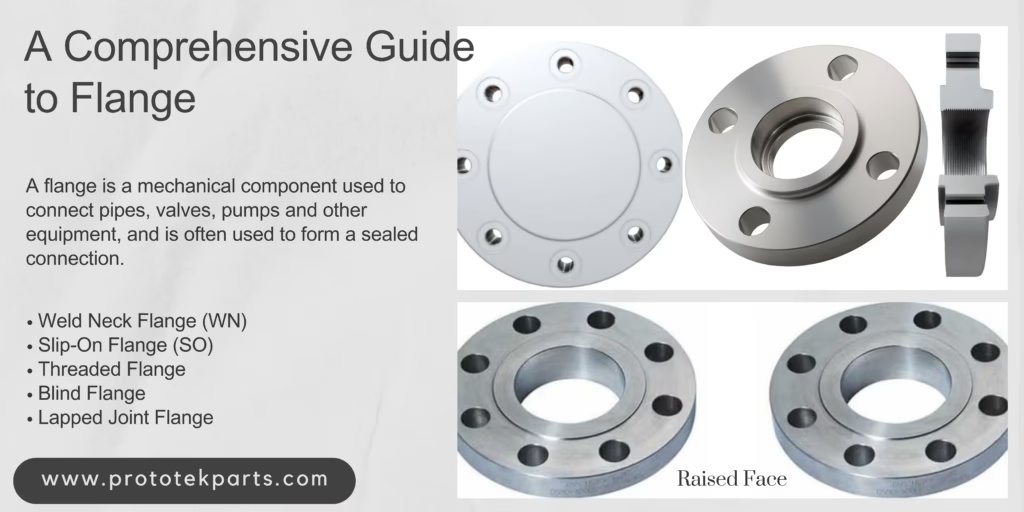

Flanş için Kapsamlı Bir Kılavuz

A Comprehensive Guide to Flange What is a flange? Brief definition: A flange is a mechanical component used to connect pipes, valves, pumps and other equipment, and is often used to form a sealed connection. Function: connection, sealing, easy maintenance (detachable), suitable for high-pressure and high-temperature occasions. Application areas: petroleum and natural gas, chemical industry, electric power, shipbuilding, water treatment, etc. Common flange types and characteristics Weld Neck Flange (WN) A butt-weld flange is a flange with a long tapered neck, the end of which is butt-welded to the pipe. Its neck gradually transitions to the thickness of the pipe, so it has good mechanical properties and stress resistance. Butt-weld flanges are suitable for high-temperature and high-pressure environments and are often used in key piping systems in industries such as oil, gas, and chemicals. This type of flange generally has a raised face (RF) or a ring joint face (RTJ). Features: With a long tapered neck, it is connected to the pipe by welding. Application: Pipe systems with high pressure, high temperature, or severe vibration (such as the petrochemical industry, and power industry). Advantages: Uniform stress distribution and strong fatigue resistance. Slip-On Flange (SO) The inner diameter of the flat welding flange is slightly larger than the outer diameter of the pipe. When installed, the flange is inserted into the end of the pipe and welded inside and outside. It has a simple structure and is easy to install. It is suitable for occasions with low pressure and less corrosiveness. Flat welding flanges are usually used in general industrial pipelines, and the joint surface can be flat (FF) or convex (RF). Features: Double-sided fillet welding after the pipe is inserted into the inner hole of the flange. Application: Low-pressure, normal temperature system (such as water treatment, low-pressure gas pipeline). Advantages: Low cost and easy installation. Threaded Flange Threaded flanges are connected to pipes with external threads through internal threads, without the need for welding, and are therefore suitable for use in situations where welding is not appropriate (such as inflammable and explosive environments). They are often used in low-pressure, small-diameter piping systems. Threaded flanges are suitable for on-site assembly and disassembly, and are also suitable for systems that are sensitive to temperature fluctuations. Features: The inner hole of the flange is threaded and connected to the pipe thread. Application: Low-pressure small-diameter pipelines (such as instrument pipelines, and fire protection systems). Advantages: No welding required, suitable for flammable and explosive environments. Blind Flange A blind flange (also called a ‘closure plate flange’) is installed at the end of a piping system to terminate a pipe. It has no center hole (bore), so there is no flow through the flange. A blind flange may be used for isolating a pipe, valve, or pressure vessel. This type of flange is available in all sizes and classes and may use a flat, raised, or ring-type joint face. Features: No center hole, is used to block the opening of the pipeline or equipment. Application: system isolation, pressure testing, or future expansion reservation. Advantages: strong sealing and high pressure bearing capacity. Lapped Joint Flange The loose flange consists of two parts: a stub end and a loose flange ring. The flange ring can rotate freely on the stub end, which is convenient for centering and installation. Since the flange body is not welded to the pipe, it can be reused and is suitable for corrosive media (often used with lined pipes), which can save expensive material costs. Features: The flange and the pipe are connected through a stub end. Application: Systems that are frequently disassembled (such as food and pharmaceutical industries). Advantages: Can be rotated for alignment, reducing installation stress. Socket Weld Flange (SW) There is a step on the inner side of the socket welding flange, which is used for inserting the pipe before corner welding. This structure is suitable for small-caliber, high-pressure systems, and has good sealing and strength after installation. Its welding part is not easy to generate eddy current or stress concentration, and is suitable for high-pressure but low-temperature occasions. Features: The pipe is inserted into the flange socket and then welded on one side. Application: Small-diameter high-pressure pipelines (such as hydraulic systems and chemical plants) Advantages: High weld strength, suitable for thin-walled pipelines. Flange Face Types Different types of flange faces serve as the contact surface for the gasket material. ASME B16.5 and B16.47 define various types of flange faces, including raised faces, large raised faces, and concave faces, which have the same dimensions to provide a relatively large contact area. Raised Face(RF) The most widely utilized type of raised face flanges in process plant applications are easily recognized. Because the gasket surface is elevated above the bolt circle, they are known as raised faces. Different gasket design combinations, such as flat ring plate types and metal composites like spiral wound and double jacketed types, are made possible by this face type. RF flanges are designed to increase the joint’s pressure-carrying capacity by applying greater pressure to a smaller gasket area. ASME B16.5 defines height and diameter according to pressure class. The height of the elevated face is determined by the flange’s pressure class. ASME B16.5 RF flanges typically have a surface polish of 125 to 250 µ in Ra (3 to 6 µ m Ra). Flat Face(FF) The bolt circle surface and the gasket surface of a flat face flange are in the same plane. Flat face flanges are usually utilized in applications where the flange fitting or mating flange is cast. Never fasten a flat face flange to a raised face flange. According to ASME B31.1, a full face gasket is needed and the raised face on the carbon steel flange must be removed when joining a flat face cast iron flange to it. This is to stop the thin, delicate cast iron flange from bouncing into the space made by the carbon steel flange’s raised face. Ring Type Joint(RTJ) For high-temperature service above 800°F (427°C) and/or high pressure (Class 600 and above), ring-type joint flanges are commonly