Quality Control and Efficiency: The Cornerstones of AC Muffler Production

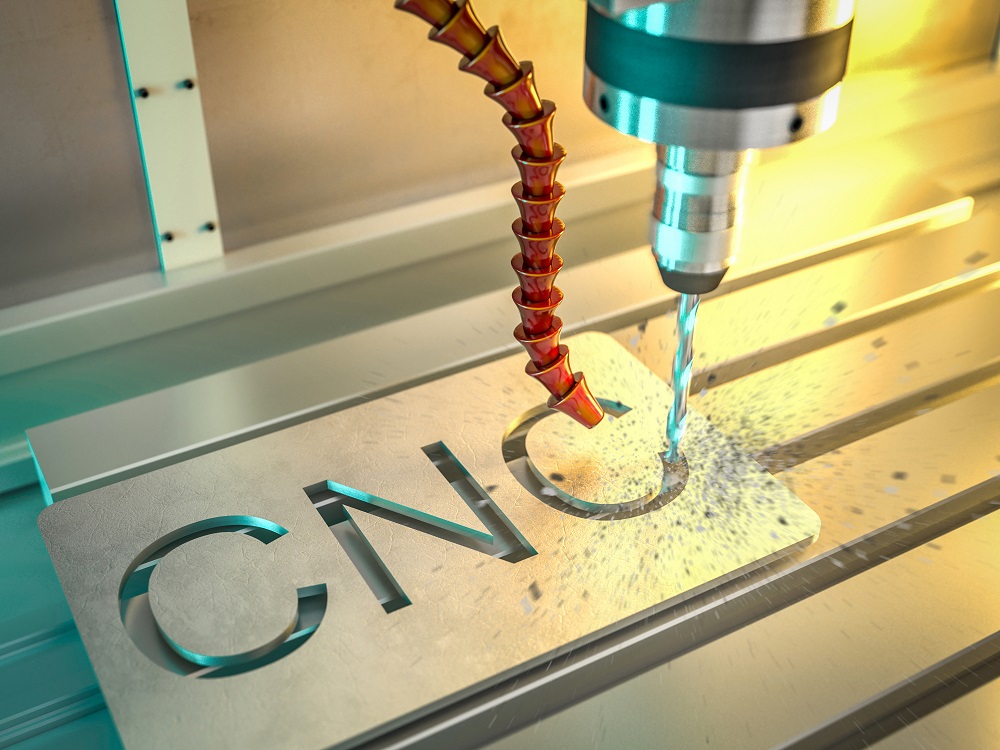

Blog Details AC mufflers are indispensable contributors to vehicle comfort and performance in the intricate web of automotive components. Ensuring their optimal functionality involves a meticulous balance between quality control and efficiency throughout production. This article delves into the pivotal role played by these two cornerstones in AC muffler manufacturing. Understanding AC Mufflers AC mufflers, also known as air conditioning mufflers, are integral components of automotive air conditioning systems. Their primary function is to reduce the noise generated by the operation of the AC compressor. As the compressor cycles on and off to regulate the temperature inside the vehicle, it can produce vibrations and oscillations that propagate through the refrigerant lines and into the cabin. AC mufflers mitigate these vibrations by absorbing and dissipating the energy, resulting in a quieter cabin environment. The importance of AC mufflers extends beyond mere noise reduction. A quieter cabin enhances the overall driving experience by reducing driver fatigue and improving passenger comfort. Moreover, AC mufflers play a crucial role in maintaining the integrity of the entire air conditioning system. Dampening vibrations and attenuating noise help prevent premature wear and tear on other AC components, extending their lifespan and reducing the likelihood of costly repairs. In recent years, there has been a growing emphasis on vehicle comfort and noise reduction in the automotive industry. As a result, the demand for high-quality AC mufflers has been steadily increasing. Manufacturers are pressured to meet stringent quality standards while optimizing production efficiency to keep pace with market demand. Additionally, advancements in automotive technology, such as the proliferation of electric and hybrid vehicles, present new challenges and opportunities for AC muffler manufacturers to innovate and adapt to evolving industry trends. Quality Control in AC Muffler Production Quality control is critical to AC muffler production, ensuring that each component meets stringent performance, durability, and safety standards. Here’s a detailed exploration of the various elements involved: Definition and Importance of Quality Control Quality control encompasses the processes and procedures to ensure products meet specified requirements and standards. In AC muffler production, adherence to rigorous quality control measures is essential to guarantee the reliability and effectiveness of the final product. By maintaining consistency and precision throughout the manufacturing process, manufacturers can uphold their reputation for delivering high-quality AC mufflers that meet customer expectations. Key Parameters for Quality Assessment Several key parameters are evaluated during the quality assessment to verify the integrity of AC mufflers: Material Quality: The quality of raw materials, such as stainless steel or aluminum, directly impacts the performance and longevity of AC mufflers. Manufacturers conduct thorough inspections to ensure that materials meet specified composition, strength, and corrosion resistance standards. Dimensional Accuracy: Precision machining and fabrication are essential for achieving dimensional accuracy in AC muffler components. Strict adherence to dimensional tolerances ensures proper fitment and compatibility with other AC system elements. Weld Integrity: Welded joints are common in AC muffler construction and must exhibit superior strength and integrity. Non-destructive testing techniques, such as ultrasonic or radiographic inspection, are employed to detect weld defects such as porosity, cracks, or incomplete penetration. Surface Finish: The surface finish of AC muffler components influences aesthetics, corrosion resistance, and aerodynamic performance. Surface treatments such as polishing, coating, or passivation are applied to achieve the desired finish while meeting quality standards. Testing Methods and Standards Various testing methods are employed to verify the performance and durability of AC mufflers, including: Pressure Testing: AC mufflers are subjected to pressure tests to ensure they can withstand the operating pressures encountered in automotive air conditioning systems. Hydrostatic or pneumatic testing verifies the integrity of welded seams and assesses the overall structural integrity of the muffler. Acoustic Testing: Sound level measurements are conducted to evaluate the noise reduction capabilities of AC mufflers. Acoustic chambers or testing facilities simulate real-world operating conditions to assess muffler performance across different frequencies and operating conditions. Vibration Analysis: Vibrational testing assesses the damping characteristics of AC mufflers and their ability to attenuate vibrations transmitted through the air conditioning system. Accelerometers and vibration analyzers measure vibration levels and frequencies to identify potential resonance issues or structural weaknesses. Compliance with Standards: AC muffler manufacturers adhere to industry standards and regulatory requirements, such as ISO 9001 or ASTM specifications, to ensure product quality and safety. Compliance with these standards provides assurance to customers and regulatory authorities regarding the reliability and performance of AC mufflers. Efficiency in AC Muffler Production Efficiency is paramount in AC muffler production to meet demand, optimize resources, and maintain competitiveness. Here’s a detailed exploration of the strategies and practices employed to enhance efficiency: Importance of Efficiency in Manufacturing Processes Efficiency in manufacturing processes directly impacts productivity, cost-effectiveness, and overall competitiveness. In AC muffler production, efficient utilization of resources, streamlined workflows, and minimized waste contribute to higher output and profitability. By embracing efficiency-enhancing practices, manufacturers can meet production targets, reduce lead times, and respond swiftly to market demands. Lean Manufacturing Principles in AC Muffler Production Lean manufacturing principles play a pivotal role in optimizing efficiency in AC muffler production: Value Stream Mapping: Identifying and eliminating non-value-added activities in the production process through value stream mapping helps streamline workflows and reduce lead times. By focusing on value-adding activities, manufacturers can enhance productivity and minimize waste. Continuous Improvement: Embracing a culture of continuous improvement fosters innovation, efficiency, and waste reduction. Regular assessment of processes, implementation of feedback mechanisms, and employee involvement in problem-solving contribute to incremental efficiency gains over time. Waste Reduction: Lean manufacturing emphasizes the elimination of waste in all its forms, including overproduction, defects, inventory, waiting times, transportation, motion, and underutilized talent. Manufacturers can enhance efficiency and competitiveness by minimizing waste and optimizing resource utilization. Technologies and Practices for Enhancing Efficiency Several technologies and practices are employed to enhance efficiency in AC muffler production: Automation: Automation technologies, such as robotic welding, CNC machining, and automated assembly systems, streamline production processes, reduce labor costs, and improve consistency and accuracy. Robotics and automation also enable manufacturers to achieve higher throughput and minimize production bottlenecks. Advanced Machining

The Essential Guide to CNC-Turned Parts Manufacturers

Blog Details In the manufacturing realm, CNC-turned parts play a pivotal role, and understanding the nuances of the manufacturers behind them is crucial. This article is a comprehensive guide to navigating the world of CNC-turned-part manufacturers, shedding light on their processes, technologies, quality control measures, industry trends, and prospects. The Craftsmanship Behind CNC Turning CNC turning, as a fundamental process in modern manufacturing, embodies a meticulous blend of craftsmanship and technological precision. At its core, CNC turning involves the removal of material from a workpiece to achieve the desired shape and dimensions. What distinguishes CNC from conventional methods is the utilization of computer numerical control (CNC) technology, which enables unparalleled accuracy and repeatability in part production. Precision Engineering Central to the craftsmanship of CNC turning is precision engineering. Manufacturers meticulously program CNC lathes, the primary machines used in turning operations, to execute precise tool movements. These movements are orchestrated to remove material from the workpiece in a controlled manner, resulting in components with tight tolerances and impeccable surface finishes. The ability to achieve micron-level precision is a hallmark of CNC turning, making it indispensable in industries where accuracy is paramount, such as aerospace, automotive, and medical device manufacturing. Material Mastery Another facet of CNC-turning craftsmanship lies in material mastery. CNC-turned parts are crafted from a wide array of materials, including metals like aluminum, steel, and titanium, as well as plastics such as nylon and polycarbonate. Each material presents challenges and considerations, from tool selection to cutting speeds and feeds. Experienced CNC machinists possess an intimate understanding of material properties and behavior, enabling them to optimize cutting parameters for maximum efficiency and quality. Tooling Expertise Tooling expertise is another crucial aspect of CNC-turning craftsmanship. Selecting cutting tools, inserts, and holders is pivotal in achieving optimal machining performance. Factors such as tool geometry, coating technology, and substrate material influence tool life, chip control, and surface finish. Moreover, the ability to strategically apply various cutting strategies, such as roughing, finishing, and profiling, requires a deep understanding of tooling principles and machining dynamics. Process Optimization Craftsmanship in CNC turning extends beyond individual machining operations to encompass process optimization. Manufacturers continuously refine their processes to minimize cycle times, reduce waste, and maximize productivity. This involves optimizing cutting parameters, such as spindle speed, feed rate, and depth of cut, to strike a balance between material removal rates and tool life. Additionally, leveraging advanced CAM (Computer-Aided Manufacturing) software allows for generating optimized tool paths, further enhancing efficiency and precision. Continuous Improvement Ultimately, the craftsmanship behind CNC turning is characterized by a commitment to continuous improvement. Manufacturers invest in training and skill development to keep pace with technological advancements and industry best practices. By embracing innovation and refining their craft, CNC machinists push the boundaries of what’s possible. Delivering precision-engineered components that drive progress across many industries. Exploring CNC Turning Technology and Equipment CNC turning technology and equipment constitute the backbone of modern manufacturing, offering unparalleled precision, versatility, and efficiency. This section delves into the intricacies of CNC-turning technology, highlighting the evolution of equipment and the innovative features that drive productivity and quality in the industry. Evolution of CNC Turning Technology The evolution of CNC turning technology has been marked by significant advancements in machine design, control systems, and cutting tool technology. Early CNC lathes were characterized by basic functionality and limited capabilities, but over the years, rapid technological progress has transformed the landscape of turning operations. Multi-Axis Machining One of the most notable advancements in CNC turning technology is adopting multi-axis machining capabilities. Traditional lathes can perform operations along two axes (X and Z). Still, modern CNC lathes can feature live tooling and additional axes (such as Y, B, and C), enabling complex machining operations in a single setup. Multi-axis machining offers greater flexibility, allowing manufacturers to produce intricate geometries and reduce the need for secondary operations. Swiss-style CNC Lathes Swiss-style CNC lathes have revolutionized the production of small, high-precision components. These machines excel at machining long, slender parts with tight tolerances, such as medical implants, aerospace components, and electronic connectors. Swiss-style lathes feature a sliding headstock and guide bushing, which provide enhanced support and stability during machining. Additionally, integrating advanced control systems and servo motors ensures precise synchronization of tool movements, resulting in superior surface finish and dimensional accuracy. Automatic Bar Feeders Automatic bar feeders are integral to CNC turning equipment, streamlining production and maximizing machine uptime. These devices automatically load raw material, typically round bars or tubes, into the lathe, allowing for continuous and unattended operation. Automatic bar feeders come in various configurations, including pneumatic, hydrodynamic, and servo-driven systems, each offering unique advantages in speed, reliability, and material handling capabilities. Live Tooling and Sub-Spindles Live tooling and sub-spindles enhance the versatility of CNC turning machines, enabling the performance of milling, drilling, and tapping operations in addition to traditional turning. Live tooling units are equipped with rotating tool holders that can engage the workpiece at various angles, expanding the range of machining capabilities. Sub-spindles, on the other hand, provide the ability to perform secondary operations on the reverse side of the workpiece, eliminating the need for manual intervention and reducing cycle times. Integration of Automation and Robotics The integration of automation and robotics has further transformed CNC turning operations, enabling lights-out manufacturing and enhancing productivity. Automated loading and unloading systems, robotic arms, and vision systems facilitate seamless material handling and part inspection. Additionally, collaborative robots (cobots) are increasingly deployed alongside human operators to perform repetitive tasks and enhance overall efficiency on the shop floor. Ensuring Quality in CNC-Turned Parts at Prototek Quality assurance is a cornerstone at Prototek in CNC-turned-part manufacturing, as precision and reliability are paramount in meeting customer expectations and industry standards. This section delves into the various measures and techniques Prototek employs to uphold stringent quality standards throughout production. Dimensional Inspection Dimensional inspection is the bedrock of quality assurance at Prototek in CNC-turned parts manufacturing. Manufacturers utilize various precision measurement tools, such as coordinate measuring machines (CMMs), calipers, micrometers, and optical comparators,

Mart Expo Promosyonu Şimdi Yayında!

Blog Details Dear Customers, In this season full of opportunities, we cordially invite you to participate in our upcoming “March Expo Promotion” event! As a company specializing in CNC machining, we have always been committed to providing customers with high-quality machining services and innovative solutions. To express our gratitude for your continued support and trust, we have prepared a wonderful promotion for you, allowing you to enjoy more benefits while shopping with us! Event Details: Duration: February 26th to March 31st, 2024 Target Audience: All customers placing orders with our company Promotion Offers: $100 off for orders ranging from $1000 to $10,000! $200 off for orders ranging from $10,001 to $30,000! $300 off for orders totaling $30,001 and above! During this sales event, we welcome both new and existing customers to inquire and place orders! Whether you are seeking machining services for specific materials or customized solutions, we can provide you with the most professional and high-quality service. Take advantage of this opportunity to establish a closer partnership with us and create a brighter future together! Our CNC machining technology and equipment are top-notch, and our team has extensive experience and expertise to meet all your machining requirements. Whether you need precision parts, complex components, or bulk production, we can provide you with satisfactory solutions. Take action now, seize this rare opportunity, and inquire or place your order today! Let’s enjoy the benefits together and grow hand in hand! Thank you for choosing us, and we look forward to seeing you at this event! Happy shopping! If you have any needs, contact us via email: Lynnyao@prototekparts.com or phone: +86-0792-86372550 Tags: Social Network: Recently Posts Online Help! +(86) 0791-86372550 WANT TO DISCUSS IN DETAIL Contact Our Consultant Now CONTACT NOW

Exploring the Pros and Cons of Custom Stainless Steel Parts by Prototek

Blog Details The demand for customized solutions is rising in today’s industrial landscape, especially regarding stainless steel parts. These components are crucial in various industries due to their corrosion resistance, strength, and durability. However, are custom stainless steel parts the best choice for your project? This article delves into the advantages and challenges associated with customization to help you make an informed decision. Advantages of Custom Stainless Steel Parts Corrosion Resistance Stainless steel is renowned for its exceptional corrosion resistance, making it an ideal choice for applications exposed to harsh environments such as marine, chemical, and food processing industries. Unlike other metals that may rust or corrode over time, stainless steel forms a passive oxide layer on its surface, which acts as a protective barrier against corrosion. By opting for custom stainless steel parts from Prototek, you can ensure that the components are specifically engineered to withstand the corrosive conditions they will encounter, leading to extended service life and reduced maintenance requirements. Strength and Durability Customized stainless steel parts from Prototek offer superior strength and durability compared to off-the-shelf options. Stainless steel exhibits excellent mechanical properties, including high tensile strength, hardness, and impact resistance, making it suitable for demanding applications in the automotive, aerospace, and construction industries. By customizing the design and material specifications, engineers can optimize the strength-to-weight ratio of stainless steel parts, resulting in lighter yet stronger components that can withstand heavy loads and harsh operating conditions without failure. Customized Design One of the primary advantages of opting for custom stainless steel parts from Prototek is the ability to tailor the design to meet specific requirements. Unlike standard components in predefined shapes and sizes, custom parts can be precisely engineered to fit the application’s exact dimensions, tolerances, and functional requirements. This flexibility allows for innovative designs that optimize performance, functionality, and aesthetics. Whether it’s intricate geometries, complex assemblies, or unique surface finishes, custom stainless steel parts can be manufactured to meet the most demanding design specifications, providing greater design freedom and customization options for engineers and designers. Material Selection Custom stainless steel parts from Prototek offer a wide range of material options, allowing engineers to select the grade of stainless steel that best suits the application’s requirements. Stainless steel alloys vary in composition, each offering unique properties such as corrosion resistance, temperature resistance, and magnetic properties. By selecting the appropriate grade of stainless steel, engineers can ensure that the components perform optimally in their intended environment, whether it’s a high-temperature furnace, a corrosive chemical processing plant, or a sterile medical device. Additionally, custom stainless steel parts can be fabricated using a variety of manufacturing processes, including machining, welding, forming, and casting, further enhancing their versatility and suitability for diverse applications. Cost Efficiency While custom stainless steel parts from Prototek may entail higher upfront costs than standard components, they often offer long-term cost savings through improved performance, durability, and reliability. Companies can minimize downtime, reduce maintenance costs, and enhance productivity by investing in custom-designed parts that meet the application’s specific needs. Additionally, custom stainless steel parts can be optimized for manufacturability, leading to greater efficiency and cost-effectiveness in the production process. By leveraging the expertise of experienced engineers and suppliers like Prototek, companies can achieve cost-efficient solutions that deliver superior performance and value over the product lifecycle. Challenges of Custom Stainless Steel Parts While there are numerous advantages to opting for custom stainless steel parts, there are also several challenges that engineers and manufacturers must navigate to ensure successful outcomes. Understanding and addressing these challenges is crucial for delivering high-quality custom components that meet the project’s performance, reliability, and cost objectives. Cost Considerations Custom stainless steel parts often incur higher upfront costs than standard off-the-shelf components. The customization process involves additional engineering, design, and manufacturing steps, as well as selecting specific materials and production techniques tailored to the application’s requirements. These factors contribute to increased production costs, which may pose challenges for budget-conscious projects or industries with tight cost constraints. Additionally, fluctuations in raw material prices, labor costs, and supply chain disruptions can further impact the cost of custom stainless steel parts, requiring careful cost management and strategic sourcing strategies to mitigate financial risks. Production Lead Times Customization typically extends the production lead time of stainless steel parts due to the additional design, engineering, and manufacturing processes involved. Unlike standard components readily available off-the-shelf, custom parts require detailed design reviews, prototyping, and testing phases to ensure they meet the desired specifications and performance requirements. Moreover, selecting specialized materials, precision machining, and complex fabrication techniques may prolong the production timeline. Managing production lead times is essential to meet project deadlines and customer expectations, requiring effective communication and coordination among stakeholders, suppliers, and manufacturers to streamline the production process and minimize delays. Technical Complexity Customizing stainless steel parts introduces technical complexities that must be carefully addressed during the design and manufacturing stages. Custom parts may require intricate geometries, tight tolerances, or advanced surface finishes that require specialized machining, welding, forming, or heat treatment. Ensuring dimensional accuracy, material integrity, and surface quality becomes paramount to meet the application’s stringent performance and reliability requirements. Moreover, selecting appropriate welding techniques, filler materials, and post-processing treatments is critical to prevent defects, distortion, or material degradation during fabrication. Overcoming these technical challenges necessitates expertise in materials science, metallurgy, and manufacturing engineering and access to state-of-the-art equipment and technologies to achieve the desired outcomes effectively. Quality Assurance Consistent product quality is essential for custom stainless steel parts to meet various industries’ stringent performance, safety, and regulatory standards. However, the customization process introduces additional variables and complexities that may impact the quality and reliability of the final components. Ensuring traceability, material certification, and compliance with industry standards becomes crucial throughout the entire production lifecycle, from raw material procurement to final inspection and testing. Implementing robust quality assurance processes, such as in-process inspections, dimensional verification, non-destructive testing, and metallurgical analysis, helps identify and rectify any deviations or defects early in the production process, minimizing rework, scrap, and warranty

Prototek Unveils the World of Customized CNC Machining Parts

Blog Details In the dynamic landscape of manufacturing, CNC machining has emerged as a pivotal force, offering precision and efficiency in the production of components. One facet that has gained significant traction is the customization of CNC machining parts, presenting a spectrum of advantages for businesses and individuals. What is CNC Machining CNC or Computer Numerical Control, is a sophisticated manufacturing process that utilizes computerized systems to control machine tools. It involves various operations, from milling to turning, and has become ubiquitous in various industries. The Need for Customized CNC Machining Parts In the realm of modern manufacturing, the demand for customized CNC machining parts has surged, driven by the unique requirements of diverse industries and individual projects. This section delves into the multifaceted reasons behind the growing need for tailored solutions, highlights the advantages over standardized components, and explores real-world success stories that underscore the impact of customization. Reasons for the Demand The demand for customized CNC machining parts stems from the inherent diversity of projects across industries. Standardized components often fall short in meeting the specific and intricate requirements of applications ranging from aerospace and automotive to medical and electronics. Customization allows for precision engineering, ensuring that each part aligns perfectly with the unique specifications of a given project. The ability to adapt designs to specific functionalities, tolerances, and environmental conditions is a driving force behind the increasing preference for customization. Industries, especially those at the forefront of technological advancements, seek tailored solutions to stay ahead in a competitive landscape. Comparison with Standard Parts A fundamental distinction between customized CNC machining and standard parts lies in adaptability. While standard parts offer mass-produced solutions suitable for broad applications, they often require more precision and specificity for cutting-edge projects. On the other hand, customized parts are crafted with meticulous attention to detail, ensuring an exact fit for the intended purpose. This tailored approach minimizes unnecessary material usage and streamlines manufacturing, resulting in optimized performance and efficiency. Success Stories in the Industry The success stories associated with customized CNC machining parts vary across industries. 1. Aerospace Advancements In the aerospace industry, where precision and reliability are non-negotiable, customized CNC machining parts have played a pivotal role in achieving breakthroughs. Tailored components designed to withstand extreme conditions and reduce weight have enhanced fuel efficiency and overall aircraft performance. 2. Medical Marvels The demand for custom CNC parts has surged in the medical field due to the need for specialized equipment and implants. Customization allows for intricate designs that match the complexity of the human body, leading to more effective and personalized medical solutions. 3. Automotive Innovations Automotive manufacturers increasingly turn to customized CNC machining to produce components that improve vehicle performance, safety, and aesthetics. From lightweight parts for fuel efficiency to intricate designs for advanced driver-assistance systems, customization drives innovation in the automotive sector. 4. Electronics Precision In the electronics industry, where miniaturization and precision are paramount, customized CNC machining parts enable the production of intricate components for devices ranging from smartphones to sophisticated electronic systems. This level of customization ensures optimal functionality and performance in electronic applications. These success stories highlight the transformative impact of customized CNC machining parts across diverse sectors. The ability to tailor components to specific needs enhances performance, fosters innovation, and pushes the boundaries of what is achievable in manufacturing. In conclusion, the burgeoning need for customized CNC machining parts is a testament to the evolving landscape of modern manufacturing. As industries continue to advance, customization becomes increasingly pivotal, offering a pathway to innovation, efficiency, and superior performance. Materials for Customized CNC Machining Customized CNC machining involves a meticulous selection of materials based on the specific requirements of each project. The choice of materials not only influences the physical properties of the finished components but also plays a crucial role in determining their performance, durability, and suitability for diverse applications. This section provides an in-depth exploration of the considerations involved in selecting different materials for customized CNC machining. Selection of Different Materials The versatility of customized CNC machining lies in its ability to work with a wide array of materials. The selection process begins with a comprehensive understanding of the project’s specifications, including mechanical, thermal, and chemical requirements. Common materials employed in customized CNC machining include metals, plastics, and composites, each offering unique characteristics that cater to specific needs. Metals Metals such as aluminum, steel, titanium, and brass are frequently chosen for their exceptional strength, durability, and heat resistance. The selection of a particular metal depends on factors like the application’s load-bearing requirements, corrosion resistance, and weight considerations. Plastics Plastics like ABS, PVC, and nylon find extensive use in customized CNC machining, particularly in industries where lightweight components and corrosion resistance are paramount. These materials are valued for their versatility, ease of machining, and suitability for applications requiring intricate designs. Composites Composite materials, combining elements like carbon fiber or fiberglass with resins, balance strength and lightness. They find applications in aerospace, automotive, and sports equipment manufacturing, where the demand for high-performance components is prevalent. Impact of Materials on Part Performance The performance of CNC-machined parts is intricately tied to the materials chosen for fabrication. The mechanical, thermal, and chemical properties of selected materials directly influence the functionality and longevity of the final components. Mechanical Properties A material’s tensile strength, hardness, and elasticity impact its ability to withstand mechanical stress and deformation. Tailoring material selection to the mechanical requirements of a project ensures the production of components capable of withstanding specific loads and forces. Thermal Properties In applications where temperature variations are a concern, thermal properties such as conductivity and expansion coefficient become critical. Choosing materials with appropriate thermal characteristics ensures stability and reliability under varying temperature conditions. Chemical Compatibility Industries exposed to harsh chemicals or corrosive environments necessitate materials with high chemical resistance. Selecting materials that can withstand exposure to specific chemicals is crucial for ensuring the longevity and performance of CNC-machined parts. Commonly Used Customization Materials Understanding the characteristics of commonly used materials in customized CNC machining is

Precision Components Manufacturers: Crafting Excellence in Manufacturing

Blog Details In the intricate landscape of modern industries, the role of precision components manufacturers like Prototek cannot be overstated. The demand for high-quality, precisely engineered parts has surged, driven by the evolving needs of sectors such as automotive, aerospace, medical devices, and electronics. This blog delves into the key aspects of precision component manufacturing, shedding light on the crucial features, selection criteria for manufacturers, applications across various industries, successful case studies, industry challenges, and future trends. Key Features of Precision Component Manufacturing Precision component manufacturing is a highly specialized field that demands meticulous attention to detail and adherence to stringent standards. The key features of precision component manufacturing encompass a range of factors, from material selection to quality control processes. Let’s delve into these critical features: Material Selection and Characteristics Choosing the right materials is the foundation of precision component manufacturing. Manufacturers must carefully assess the properties of materials to ensure they meet the specific requirements of the intended application. Factors such as strength, durability, corrosion resistance, and thermal conductivity play a crucial role in material selection. Common materials used in precision manufacturing include various metals, alloys, and advanced composites. Manufacturing Processes and Technologies Precision components are crafted using advanced manufacturing processes and cutting-edge technologies. CNC (Computer Numerical Control) machining is a prevalent technique that enables high-precision and repeatable production. Additionally, 3D printing has gained prominence for its ability to create intricate and complex geometries with unmatched precision. These technologies contribute to the consistent quality and accuracy of precision components. Quality Control and Inspection Methods Maintaining stringent quality control is paramount in precision component manufacturing. Manufacturers employ sophisticated inspection methods to ensure that each component meets the specified tolerances and standards. Coordinate Measuring Machines (CMMs) are used to precisely measure the geometric characteristics of components. Non-destructive testing (NDT) methods, such as X-ray and ultrasonic testing, are employed to detect internal defects without compromising the integrity of the components. Tolerance and Precision Precision components are characterized by extremely tight tolerances, often measured in micrometers. Achieving such precision requires a combination of advanced machinery, skilled craftsmanship, and rigorous quality assurance processes. Manufacturers must consistently meet these tight tolerances to ensure the proper functioning and compatibility of the components within larger systems. Surface Finish and Coating The surface finish of precision components is a critical aspect that impacts both aesthetics and functionality. Manufacturers employ techniques like polishing, grinding, and coating to achieve the desired surface characteristics. Coatings may include protective layers to enhance durability, reduce friction, or provide resistance to environmental factors such as corrosion. Customization Capabilities Precision component manufacturers often offer customization capabilities to meet the unique requirements of different industries and applications. The ability to tailor components to specific dimensions, materials, and functionalities is a key feature that distinguishes top-tier manufacturers in this field. Continuous Improvement Practices Staying at the forefront of precision manufacturing requires a commitment to continuous improvement. Manufacturers invest in research and development to explore innovative techniques, materials, and technologies. Embracing a culture of continuous improvement ensures that precision component manufacturers like Prototek remain competitive in an ever-evolving industrial landscape. In conclusion, the key features of precision component manufacturing underscore the intricate processes and high standards involved in producing components that meet the demanding requirements of modern industries. From material selection to quality control, precision is not just a goal but a fundamental aspect that defines the excellence of manufacturers like Prototek in this specialized field. Criteria for Choosing Precision Component Manufacturers Selecting the right precision component manufacturer is a critical decision that directly impacts the quality, reliability, and efficiency of the final products. Several key criteria guide this decision-making process, ensuring that manufacturers like Prototek align with the specific needs and standards of their clients. Here, we explore in detail the essential criteria for choosing precision component manufacturers: Quality Certifications and Standards Reputable precision component manufacturers like Prototek adhere to industry-recognized quality certifications and standards. These certifications validate the manufacturer’s commitment to maintaining high-quality production processes and meeting rigorous specifications. ISO certifications, such as ISO 9001 for quality management systems, are often considered a benchmark for excellence. Clients should verify that manufacturers hold relevant certifications to ensure the consistency and reliability of the produced components. Timely Delivery and Supply Chain Management Meeting project deadlines is crucial in industries that rely on precision components. Manufacturers like Prototek with efficient supply chain management systems can provide a competitive advantage. The ability to procure raw materials promptly, manage inventory effectively, and optimize production schedules contributes to timely deliveries. Clients should assess a manufacturer’s track record in meeting deadlines and inquire about their supply chain practices to ensure a seamless and reliable flow of components. Cost-Effectiveness Analysis While quality is paramount, cost-effectiveness is also a critical consideration. Clients seek manufacturers like Prototek who can deliver high-quality precision components at competitive prices. A thorough cost-effectiveness analysis involves evaluating the overall value proposition, considering factors such as material costs, production efficiency, and long-term reliability. Manufacturers like Prototek that strike a balance between quality and cost-effectiveness are often preferred partners. Reputation and Customer Reviews A manufacturer’s reputation within the industry is a key indicator of its capabilities and reliability. Clients should research and consider the manufacturer’s track record, including successful projects, customer satisfaction, and any industry recognition. Additionally, reading customer reviews and testimonials provides insights into the real-world experiences of other clients. A positive reputation and satisfied customers are indicative of a manufacturer’s commitment to excellence. Flexibility and Customization The ability to accommodate customization requirements is essential, especially in industries with diverse and unique needs. Clients should assess a manufacturer’s flexibility in adapting to specific design specifications, material preferences, and production volumes. Manufacturers like Prototek that offer customization capabilities demonstrate an understanding of the client’s individual requirements and can provide tailored solutions. Communication and Collaboration Effective communication and collaboration are critical throughout the manufacturing process. Clients should evaluate a manufacturer’s communication practices, responsiveness, and willingness to collaborate closely on projects. Transparent communication ensures that any challenges are promptly addressed, and clients remain