Understanding Pump Covers in the Automotive Industry

Every part is essential to maintaining the longevity and optimum performance of cars in the dynamic automotive industry. Although they may not always be the most visible of these parts, pump covers are essential for safeguarding the many kinds of pumps found in automobiles. This article explores the types, advantages, and uses of pump covers in the automotive industry.

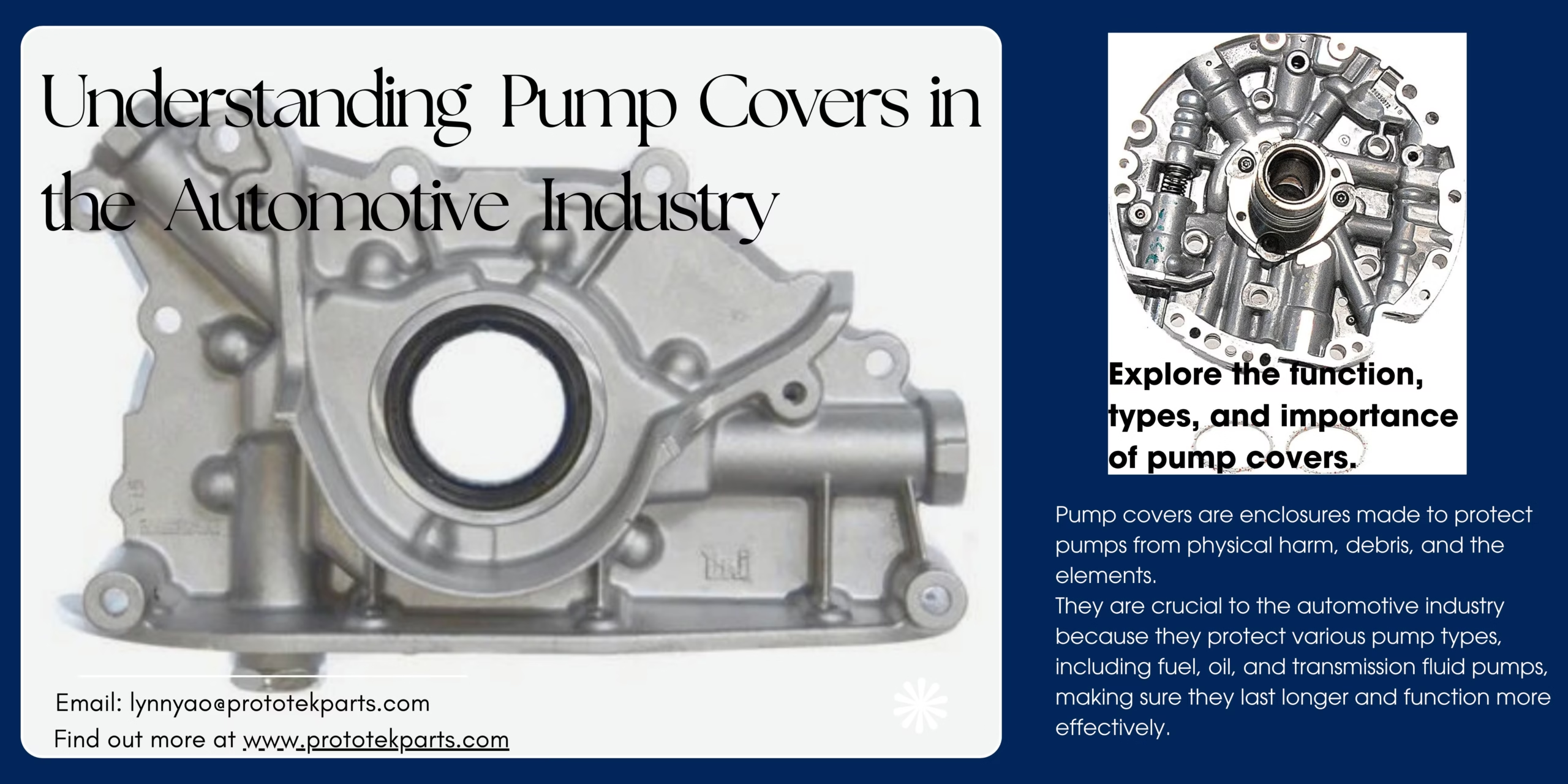

Pump Covers: What Are They?

Pump covers are enclosures made to protect pumps from physical harm, debris, and the elements. They are crucial to the automotive industry because they protect various pump types, including fuel, oil, and transmission fluid pumps, making sure they last longer and function more effectively.

Pump Cover Types in the Automobile Sector

1. Oil Pump Covers

Oil pump covers are essential to preserving the integrity of a car’s oil pump system. They keep impurities out of the oil system, which can cause wear and tear on engines. According to 4 Wheel Parts, oil pump covers are made to fit particular car models directly and are available for a variety of engines, including AMC V8 engines.

2. Covers for Transmission Fluid Pumps

The purpose of transmission fluid pump covers is to safeguard the pumps that circulate transmission fluid within the transmission system. According to JEGS High Performance, these covers are crucial for stopping fluid leaks and preserving the transmission system’s effectiveness. They are available in a variety of designs, some of which have integrated coolers for improved efficiency.

3. Covers for fuel pumps

Fuel pump covers are essential for protecting fuel pumps from harm and guaranteeing proper operation. Although they aren’t talked about as much as oil or transmission fluid pump covers, they are just as crucial to preserving the integrity of the car’s fuel system.

Benefits of Using Pump Covers

- Protection from Environmental Elements

Pump covers are primarily designed to protect pumps from harsh environmental conditions such as rain, snow, and dust. This protection is crucial for pumps installed outside the vehicle or in exposed areas. Grainger Industrial Supply emphasizes that pump covers allow pumps to operate outside without ambient debris or weather causing damage.

- Enhanced Pump Longevity

By shielding pumps from contaminants and physical damage, pump covers extend the life of the pumps. This longevity translates into cost savings for vehicle owners, as it reduces the frequency of pump replacements and repairs.

- Improved Vehicle Performance

Well-protected pumps operate more efficiently, contributing to the overall performance of the vehicle. For instance, a well-maintained oil pump ensures proper lubrication of engine components, leading to smoother engine operation.

- Cost-Effectiveness

Investing in high-quality pump covers can lead to significant cost savings in the long run. By preventing damage and reducing maintenance needs, pump covers help vehicle owners avoid expensive repairs and replacements.

Applications of Pump Covers in the Automotive Industry

- Commercial Vehicles

In commercial vehicles, such as trucks and buses, pump covers are essential for protecting the larger and more exposed pumps. These vehicles often operate in harsh conditions, making pump covers a necessary component for maintaining reliability and performance.

- Off-Road Vehicles

Off-road vehicles, including Jeeps and ATVs, are frequently exposed to extreme conditions, such as mud, water, and debris. Pump covers are crucial in these vehicles to ensure that pumps remain functional and protected during off-road excursions.

- Performance and Racing Vehicles

In performance and racing vehicles, every component must operate at peak efficiency. Pump covers help maintain the optimal performance of pumps, contributing to the overall speed and reliability of these high-performance vehicles.

Choosing the Right Pump Cover

When selecting a pump cover, it is essential to consider factors such as material, fit, and compatibility with the specific pump type. High-quality materials, such as those used in ALCO Covers, provide excellent resistance to environmental elements, ensuring long-lasting protection.

Material Considerations

Durability: Choose materials that can withstand harsh conditions, such as industrial-strength vinyl or polyethylene.

Weather Resistance: Opt for covers that offer protection against UV rays, rain, and extreme temperatures.

Fit and Compatibility: Ensure the cover is designed to fit the specific pump model and application.

In conclusion

In the automotive industry, pump covers are a crucial but frequently disregarded component. They are essential to the upkeep and effectiveness of automobiles because they offer protection, increase longevity, and boost performance. Purchasing high-quality pump covers is a smart move that can result in significant cost savings and increased vehicle reliability, whether for performance, off-road, or commercial vehicles.

Examining your options for pump covers is a good first step if you’re thinking about improving the longevity and performance of your car. Consider contacting industry suppliers or automotive specialists for additional information on choosing the best pump cover for your requirements. They can help you make an informed choice.

In summary, pump covers are not merely add-ons; rather, they are vital parts that greatly enhance the general functionality and health of automotive systems. For smooth operation and a longer service life, make sure your car has the best pump covers installed.

If you have any needs, contact us via email at Lynnyao@prototekparts.com or phone: +86-0792-86372550

Tags:

- Pump Cover