冷锻与热锻

In advanced manufacturing, choosing cold and hot forging can significantly impact your components’ quality, strength, and cost-effectiveness. At Prototek, we specialize in delivering superior forging solutions tailored to meet the exacting demands of various industries. This article explores the differences, advantages, and applications of cold and hot forging, showcasing how Prototek’s expertise can elevate your production processes.

Understanding Cold Forging

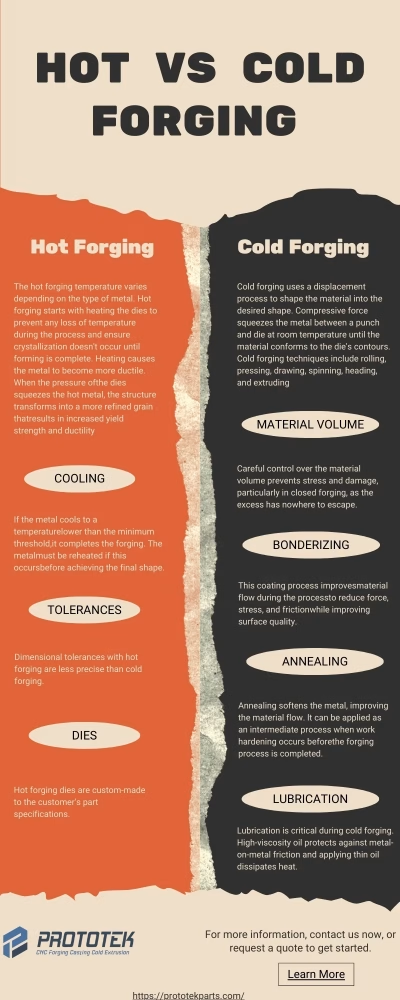

Cold forging, or cold working, involves molding metal at or close to room temperature. Through this process, the material holds its unique glass-like structure, which results in expanded hardness and rigidity. The process is not like hot fashioning because the metal isn’t warmed, instead it’s worked in its room-temperature state, below its recrystallization state.

Precision in Cold Forging

Cold forging involves shaping metal at room temperature or slightly above, using high-pressure dies to form the desired shape. This process is ideal for producing intricate components with excellent dimensional accuracy and surface finish. At Prototek, our cold forging capabilities are backed by state-of-the-art equipment and seasoned craftsmanship, ensuring reliable performance for diverse applications.

Advantages of Cold Forging at Prototek:

1. Material Conservation: Cold forging minimizes waste using precise die designs and controlled deformation. This efficiency translates into cost savings and environmental benefits for our clients.

2. Enhanced Mechanical Properties: Due to strain hardening, components forged through cold forging exhibit superior strength, toughness, and surface hardness. Prototek optimizes forging parameters to achieve optimal mechanical properties.

3. Complex Geometries: Cold forging produces complex shapes and features with tight tolerances. Prototek’s engineering expertise and CAD/CAM capabilities ensure seamless design and production integration.

4. Cost-Effective Solutions: Cold forging offers a cost-effective solution for high-volume production runs by reducing machining and material costs. Prototek’s streamlined processes and efficient workflow deliver competitive pricing without compromising quality.

5. Versatility Across Industries: From automotive and aerospace to consumer electronics and medical devices, cold forging serves a wide range of industries where precision and reliability are paramount.

Delving into Hot Forging

Hot forging, or hot working, includes shaping metal at raised temperatures, usually between 700°C and 1,200°C. The metal is heated to provide flexibility and make it more bendable.

Strength and Durability in Hot Forging

Hot forging involves heating metal above its recrystallization temperature and then shaping it using dies. This process enhances the material’s plasticity, allowing for easier deformation and superior mechanical properties in the finished parts. Prototek’s hot forging capabilities leverage advanced technology to deliver robust solutions for demanding applications.

Advantages of Hot Forging at Prototek:

1. High Strength-to-Weight Ratio: Hot forged parts exhibit exceptional mechanical properties, including high tensile strength, impact resistance, and fatigue strength. Prototek optimizes forging temperatures and dwell times to achieve desired material characteristics.

2. Dimensional Accuracy: Hot forging allows for precise control over grain structure and flow lines, resulting in parts with excellent dimensional stability and uniformity. Prototek’s meticulous process controls ensure consistent quality across production batches.

3. Complex Part Designs: While suitable for simpler geometries, hot forging is particularly practical for parts requiring significant deformation or thick cross-sections. Prototek’s engineering team collaborates closely with clients to optimize designs for hot forging feasibility.

4. Cost-Efficiency in Bulk Production: Hot forging offers economies of scale in large-scale production runs despite higher initial setup costs. Prototek’s strategic tooling and process optimization approach maximizes efficiency and minimizes per-part costs.

5. Wide Application Spectrum: From industrial machinery components to specialized fittings and fasteners, hot forging serves industries demanding robust, high-performance parts subjected to extreme conditions.

Making the Right Choice with Prototek

Why Choose Prototek for Forging Solutions?

1. Expertise and Innovation: With decades of experience in precision manufacturing, Prototek combines industry-leading expertise with innovative forging technologies to meet evolving market demands.

2. Customized Solutions: Whether you require prototype development, small-batch production, or full-scale manufacturing, Prototek offers tailored forging solutions to optimize performance and reduce time-to-market.

3. Quality Assurance: Prototek adheres to stringent standards throughout the forging process, ensuring every component meets or exceeds customer expectations for durability, reliability, and performance.

4. Collaborative Partnership: We prioritize client collaboration, providing responsive communication, flexible solutions, and proactive project management to ensure seamless project execution and satisfaction.

5. Comprehensive Service Offering: From initial design consultation to final inspection and delivery, Prototek offers end-to-end forging solutions under one roof, streamlining processes and enhancing overall project efficiency.

Conclusion

In conclusion, choosing between cold and hot forging depends on specific project requirements, including material properties, part complexity, production volume, and cost considerations. At Prototek, we empower you to make informed decisions by offering unparalleled expertise, cutting-edge technology, and a commitment to excellence in every forging solution we deliver.

Contact Prototek today to discuss your forging needs and discover how we can optimize your production processes with precision, strength, and reliability—partner with Prototek to forge solutions that elevate your products to new heights of performance and durability.

If you have any needs, contact us via email at Lynnyao@prototekparts.com 或致电+86-0792-86372550

标签

- hot forging,cold forging