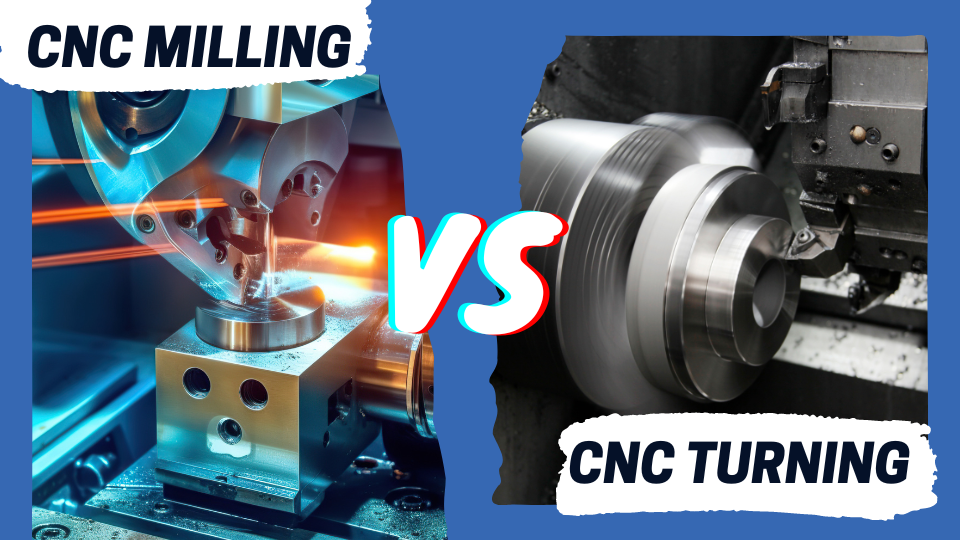

数控铣削与数控车削

In today’s rapidly evolving manufacturing landscape, precision and efficiency are paramount. Choosing the proper machining process is crucial in aerospace, automotive, medical devices, or any other industry requiring intricate components. At Prototek, we deliver high-quality CNC machining solutions tailored to meet diverse client needs. This article explores the differences, advantages, and applications of CNC milling and turning, empowering you to make informed decisions for your projects.

Understanding CNC Milling

The Art of CNC Milling

CNC milling involves using rotary cutting tools to remove material from a workpiece, creating complex shapes and features. This process is ideal for producing components with detailed designs and strict dimensional tolerances. At Prototek, our CNC milling capabilities are at the forefront of precision manufacturing, allowing us to cater to various industries and applications.

Advantages of CNC Milling at Prototek

1. Precision and Versatility: CNC milling excels in machining parts that require high precision and intricate geometries. Our state-of-the-art milling machines and CAD/CAM software ensure consistent accuracy, meeting even the most demanding specifications.

2. Material Flexibility: CNC milling accommodates various materials, from aluminum and stainless steel to plastics and composites. This versatility enables Prototek to serve clients across multiple industries, from prototyping to production.

3. Complexity Handling: We leverage advanced technologies to efficiently tackle complex designs involving 3-axis, 4-axis, or 5-axis milling. Prototek’s engineering expertise ensures optimal tool paths and machining strategies for each project.

4. Rapid Prototyping and Short Runs: With efficient programming and setup, Prototek delivers rapid prototyping services and seamlessly handles small to medium production runs. This agility is crucial for accelerating product development cycles and meeting tight deadlines.

5. Quality Assurance: Rigorous quality control measures, including in-process inspections and final checks, guarantee that every component meets the highest standards before leaving our facility.

Delving into CNC Turning

Mastering CNC Turning Techniques

CNC turning revolves around rotating a workpiece while cutting tools remove material to create cylindrical shapes and symmetrical parts. This process is highly efficient for producing axially symmetric components with minimal setup times, making it cost-effective for large-scale production runs.

Advantages of CNC Turning at Prototek

1. Efficiency and Speed: CNC turning produces cylindrical parts quickly and efficiently. Prototek’s advanced turning centers and skilled operators ensure consistent performance and rapid turnaround times for our clients.

2. Cost-Effectiveness: CNC turning offers significant cost advantages over other machining methods for high-volume production runs. Prototek optimizes material usage and production processes to deliver competitive pricing without compromising quality.

3. Versatility in Component Size: Whether small precision parts or more significant components up to a specific diameter and length, CNC turning accommodates a wide range of sizes and shapes. This versatility caters to diverse industry needs, from automotive components to medical instruments.

4. Surface Finish and Tolerance Control: Prototek ensures superior surface finishes and tight dimensional tolerances in every turned component with fine-tuned cutting parameters and tooling selection. This attention to detail is critical for meeting functional and aesthetic requirements.

5. Consistency and Reliability: Prototek maintains stringent quality controls throughout the turning process, from initial setup to final inspection. Our commitment to reliability ensures that each part meets customer specifications and exceeds expectations.

Choosing the Right Methodology

Factors Influencing Your Decision

When deciding between CNC milling and CNC turning for your project, several factors come into play:

1. Part Complexity: Complex geometries and features often favor CNC milling because they can maneuver in multiple axes and perform intricate cuts.

2. Material Type: Consider the material’s hardness, machinability, and specific properties. CNC milling is versatile and uses a wide range of materials, while CNC turning is efficient for softer metals and plastics.

3. Production Volume: CNC milling offers flexibility and rapid turnaround for small batches and prototypes. Conversely, CNC turning is optimal for high-volume production due to its efficiency and lower per-part cost.

4. Tolerance Requirements: Evaluate the required dimensional accuracy and surface finish. Both processes can achieve tight tolerances, but the approach may vary based on part geometry and material.

5. Lead Time and Cost: Assess project timelines and budget constraints. Prototek’s streamlined processes ensure competitive pricing and timely delivery, supporting your project’s success.

Prototek’s Commitment to Excellence

Why Choose Prototek?

At Prototek, we are more than a CNC machining service provider – your strategic partner in innovation and manufacturing excellence. Here’s why clients trust us:

1. Advanced Technology: Our cutting-edge CNC equipment and software investment ensures superior precision and efficiency across all projects.

2. Expertise and Experience: With decades of experience in precision machining, our team of engineers and machinists delivers innovative solutions tailored to your needs.

3. Quality Assurance: From initial design consultation to final inspection, Prototek adheres to rigorous quality standards to deliver flawless components that meet or exceed industry requirements.

4. Customer Focus: We prioritize client satisfaction, offering responsive communication, flexible solutions, and proactive project management to ensure your expectations are met and exceeded.

5. End-to-End Solutions: Whether you need rapid prototyping, small-batch production, or full-scale manufacturing, Prototek provides comprehensive CNC machining services under one roof.

Conclusion

In conclusion, CNC milling and turning are integral to modern manufacturing, each offering unique advantages depending on project requirements. At Prototek, we leverage our expertise, advanced technology, and commitment to quality to deliver exceptional results for our clients. Whether launching a new product, refining an existing design, or scaling production, our CNC machining capabilities empower you to achieve your goals efficiently and cost-effectively.

Contact Prototek today to discuss your CNC machining needs and discover how we can elevate your projects from concept to reality—partner with us for precision, reliability, and innovation in manufacturing.

If you have any needs, contact us via email at Lynnyao@prototekparts.com 或致电+86-0792-86372550

标签

- cnc turning,cnc milling